What are the impacts of the bubbles in coating

The presence of bubbles in a coating can have several detrimental impacts on both the aesthetic and functional aspects of the coating. These impacts include:

-

Uneven Appearance: Bubbles can create an uneven, rough surface, detracting from the smooth, uniform finish that is typically desired.

-

Visible Defects: Once the bubbles burst, they can leave behind small craters or pinholes, which are visually unappealing and can be particularly problematic in high-gloss finishes.

-

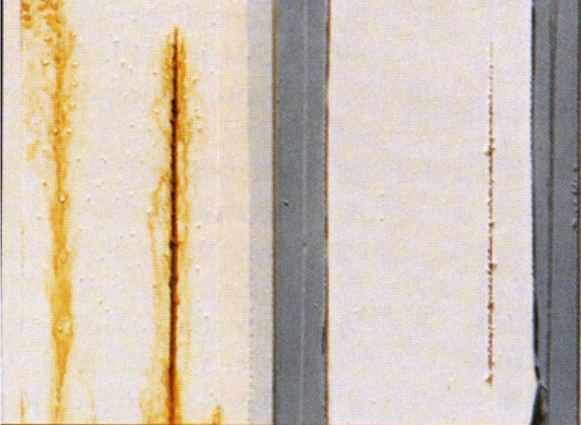

Bubbles can create weak points in the coating where the protective layer is thinner, reducing the overall effectiveness of the coating in protecting the underlying material.

-

Corrosion Vulnerability:

-

The presence of bubbles can interfere with the adhesion of the coating to the substrate, leading to peeling or flaking over time.

-

Intercoat Adhesion Issues:

-

Bubbles can compromise the structural integrity of the coating, making it more prone to damage from physical impacts or environmental stress.

-

Altered Flexibility:

-

Coatings with bubbles may degrade faster than those without, leading to a reduced lifespan and increased maintenance or reapplication costs.

-

Quality Perception:

In summary, the presence of bubbles in a coating not only affects its visual appeal but also undermines its protective qualities, mechanical integrity, and overall performance. Proper application techniques and conditions, along with the use of high-quality materials, are key to avoiding bubble formation and ensuring the long-term effectiveness and durability of the coating.