1.The Leveling Principle of Leveling Agents

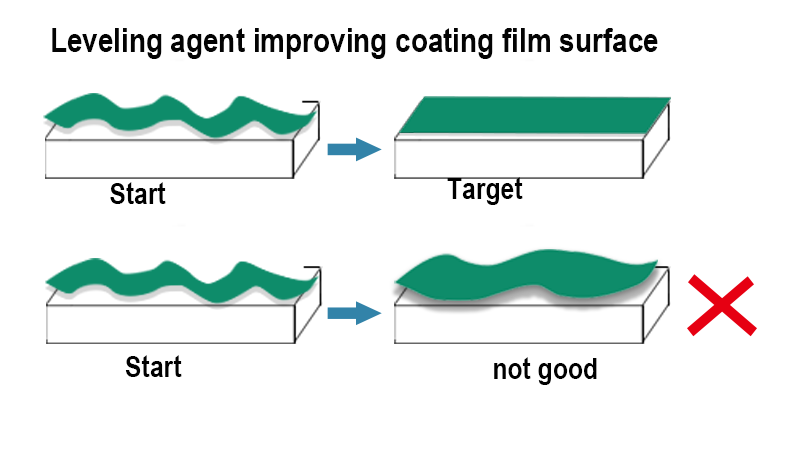

1.1 Leveling agents improving the paint film surface

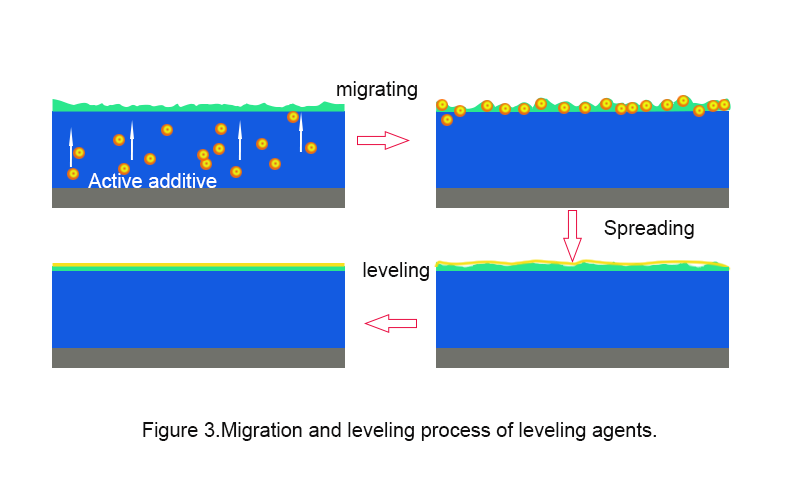

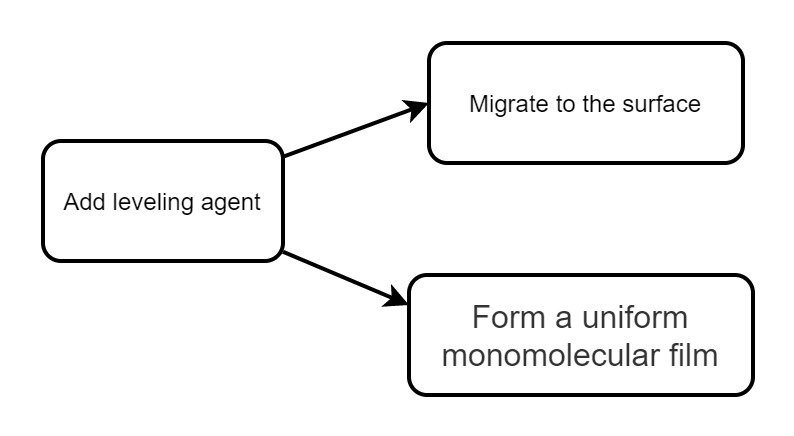

In coatings, we usually refer to the additive that can promote the flow of the paint film and help achieve a smooth surface as a leveling agent. The precondition for a leveling agent to work is that it can spontaneously migrate to the surface of the paint film and affect the surface tension and surface tension gradient distribution of the paint film.

1.2 About leveling time during leveling process

Leveling time formula

-

The flow time is positively correlated with viscosity, which means the higher the viscosity, the longer the required flow time.

-

The flow time is negatively correlated with the cube of the paint film thickness, which means it is easier to achieve good flow with thicker films.

-

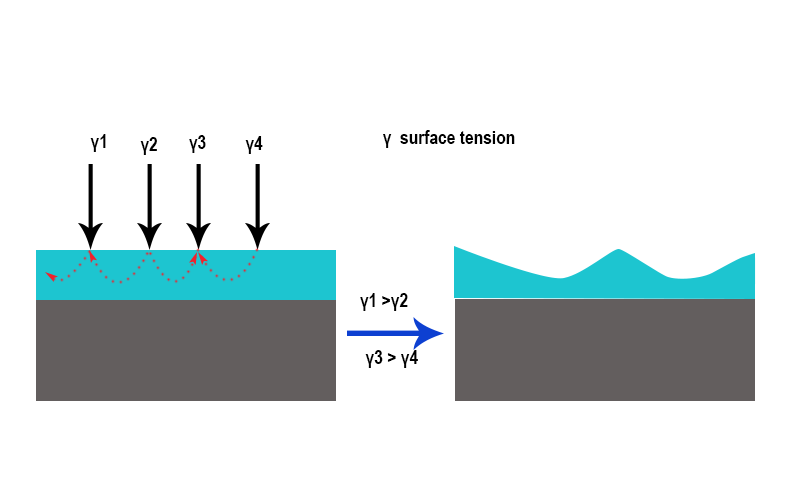

The flow time is also negatively correlated with the surface tension of the paint film, which means the lower the surface tension, the longer the flow time needed to achieve good leveling.

1.3 leveling agent migrate to the surface and keep the paint film smooth

During the drying process of the paint film, leveling agents can migrate to the surface of the film and form a monomolecular film with a constant surface tension that does not change with the film forming process. With the help of leveling agents, the surface tension of the paint film can be kept constant, and the film can gradually reach a relatively smooth surface without disturbance under its own driving force.

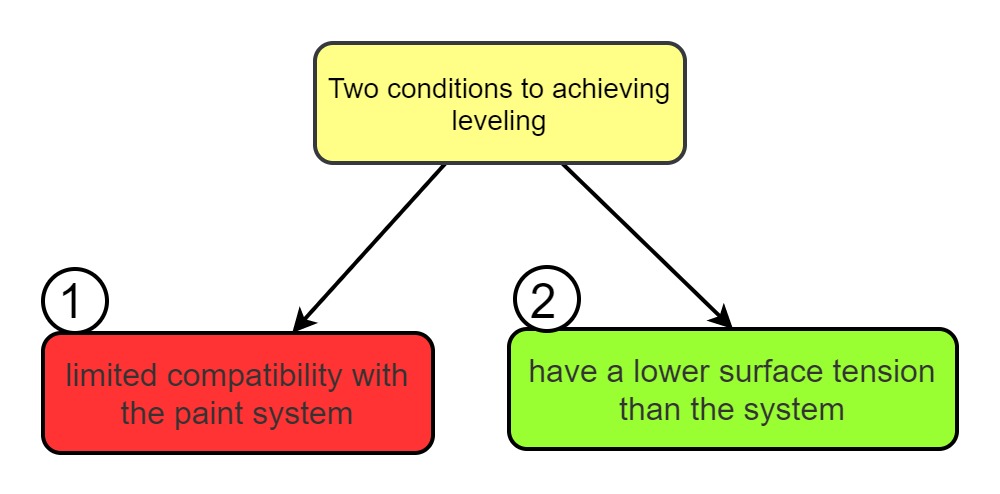

1.4 Two conditons to achieving leveling

The function of leveling agent

Two conditions for achieving leveling

2.Categories of Leveling Agents

Silicone-based leveling agents and silicone-free (non-silicone) leveling agents are two main types of leveling agents used to improve the leveling of paint films. They have different properties and advantages depending on their chemical composition and application.

Silicone-based leveling agents:

Silicone-free leveling agents:

Factors Affecting Silicone Leveling Agents

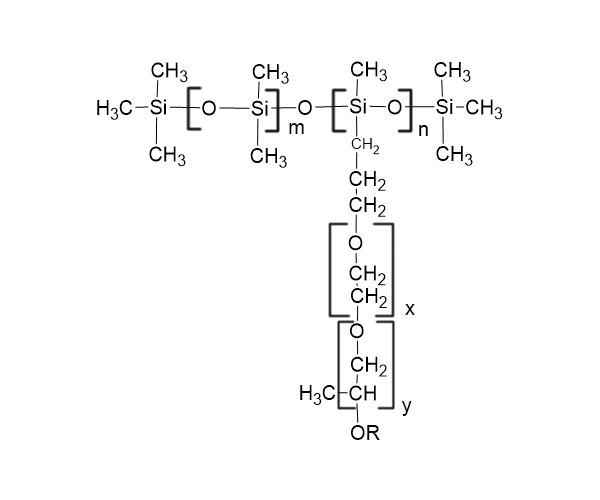

Currently, in the coatings industry, the organic silicone leveling agents used are various modified silicone oils, with the largest number of varieties being polyether-modified silicone oils. The structural formula is shown in the figure. Since there are four adjustable parameters in it, namely m, n, x, and y, selecting the appropriate parameters allows for the production of organic silicone leveling agent products with a wide range of performance variations.

From a structural perspective, the two most significant parameters that affect the performance of organic silicone leveling agents are silicon content and molecular weight, especially the level of silicon content, which directly determines the performance of the corresponding organic silicone leveling agent.

Higher the silicon content, the better the leveling agent’s ability to reduce surface tension, resulting in a better tactile feel and improved resistance to shrinkage holes. When the silicon content exceeds a certain threshold, it also provides noticeable defoaming performance. However, compatibility decreases as silicon content increases, and when silicon content reaches a certain level, it can no longer be used in high-gloss systems.

Lower silicon content, on the other hand, improves compatibility, although it reduces the ability to resist shrinkage holes and increases surface tension, thereby enhancing leveling effects. Additionally, when silicon content decreases to a certain level, the surface activity of the additive significantly decreases, leading to reduced foam stability. Therefore, in practical use, it is crucial to select a product with an appropriate silicon content based on specific requirements.

In accordance with the levels of silicon content and molecular weight, they can be categorized into the following major groups, each of which exhibits unique performance characteristics:

| Low Silicon Content | Medium Silicon Content | High Silicon Content | |

| Low Molecular Weight | Substrate Wetting | Rapid Leveling | Anti-shrinkage Agent |

| Medium Molecular Weight | Outstanding Leveling | Outstanding Performance | Tactile Additive |

| High Molecular Weight | Outstanding Leveling | Emphasis on Leveling, Wear Resistance | Wear Resistance, Anti-Skid |

DCA silicone leveling agent in each major category is as following

| Low Silicon Content | Medium Silicon Content | High Silicon Content | |

| Low Molecular Weight | DCA-1635 DCA-1042 |

DCA-233 | DCA-1433 |

| Medium Molecular Weight | DCA-1331 DCA-131 |

DCA-156 DCA-1437 |

DCA-1421 |

| High Molecular Weight | DCA-179 | DCA-1373 | DCA-1431 |

3.Properties of Leveling Agents

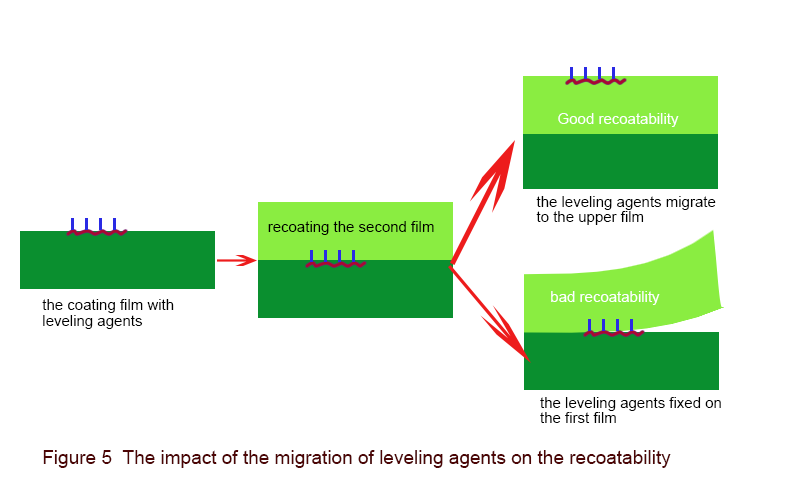

3.1The Influence of Silicone Leveling Agents on Recoatability

The impact of leveling agents on recoatability is primarily related to the migration of leveling agents between paint films, as illustrated in the diagram. After the paint film is formed, leveling agents generally migrate to the surface of the film. When recoating the paint film, if the leveling agent can freely migrate between the paint films, meaning it can quickly migrate to the new surface, its impact on recoatability is relatively minor.

Conversely, if for some reason, the leveling agent becomes fixed on the surface of the paint film (e.g., due to chemical reactions or large molecular weight resulting in stronger van der Waals forces with the paint film), its free migration is restricted, which can have adverse effects on recoatability, and interlayer adhesion can also be significantly affected.

Among the various factors that affect recoatability due to leveling agents, the functional groups carried by the leveling agent that react with the applied resin system are the most significant.

For example, in polyurethane systems, if the leveling agent contains hydroxyl groups, during the curing process of the paint film, the hydroxyl groups present in the leveling agent can react with the isocyanate groups in the coating, thereby becoming fixed on the surface of the paint film. When the number of organic silicone leveling agents fixed on the surface of the paint film reaches a certain level, it can adversely affect recoatability, a phenomenon that has been confirmed by numerous experiments.

| Coating System | Levelling Agent Functional Groups That May Affect Recoatability |

| Polyurethane System | Hydroxyl, Isocyanate Ester Groups |

| Amino Baking Paint System | Hydroxyl, Carboxyl Groups |

| UV-Cured System | Acrylate Groups, Amino Groups |

| Epoxy System | Epoxide or Amino Groups |

To avoid adverse effects on the recoatability of coatings caused by the functional groups carried by leveling agents, it is advisable to choose organic silicone leveling agents that do not contain functional groups when making the selection. This helps prevent the involvement of end groups in resin cross-linking reactions, which could lead to a loss of recoatability in the system.

In Deco Chemical Additives most organic silicone leveling agents are produced without functional groups. The table below lists the functional groups carried by DCA’s organic silicone leveling agents.

| Functional Groups | Item |

| No Functional Group | DCA-110 |

| DCA-179 | |

| DCA-233 | |

| DCA-131 | |

| DCA-156 | |

| HydroxylGroup | DCA-1373 |

| DCA-1122 | |

| Acrylate Group | DCA-1221 |

| DCA-1232 |

3.2 The Influence of Organic Silicone Leveling Agent Structures on High-Temperature Resistance

In typical baking paint systems, where higher temperatures are used, conventional polyether-modified silicone-based leveling agents can present challenges. This is because the polyether chains within them tend to gradually decompose after temperatures exceed 150 degrees Celsius, producing small molecular fragments. These decomposition by-products often lead to various paint film defects, such as shrinkage and poor recoatability.

As a result, polyether-modified silicone-based leveling agents are suitable for use in baking paint systems below 150 degrees Celsius. However, when used in baking paint systems operating above 150 degrees Celsius, it becomes necessary to employ organic silicone leveling agents with high-temperature resistance.

Depending on specific usage requirements, there are various types of organic silicone leveling agents suitable for high-temperature systems. Among the common modified organic silicone leveling agents, polyamide-modified and aromatic group-modified organo silicon are two major types used in high-temperature systems. Polyamide-modified organic silicone leveling agents typically exhibit good compatibility and can be used in high-temperature systems with high compatibility requirements. Aromatic group-modified organic silicone leveling agents, on the other hand, have certain compatibility limitations and are typically used in color paint systems. However, they can provide additional defoaming properties.

Deco Chemical set up 2004, the factory set up at 2014

Deco chemical is a technology-oriented company specializing in the business of coating additives.

Under factory support, you can expect punctual product delivery and consistent quality maintenance.

In 2022, the sales revenue was 28 million usd, and the additives sales volume was approximately 4600 tons

There are 3 technical center to support our business,They are located at Shanghai, Guangdong and Chongqing

Chemical laboratory at Foshan City

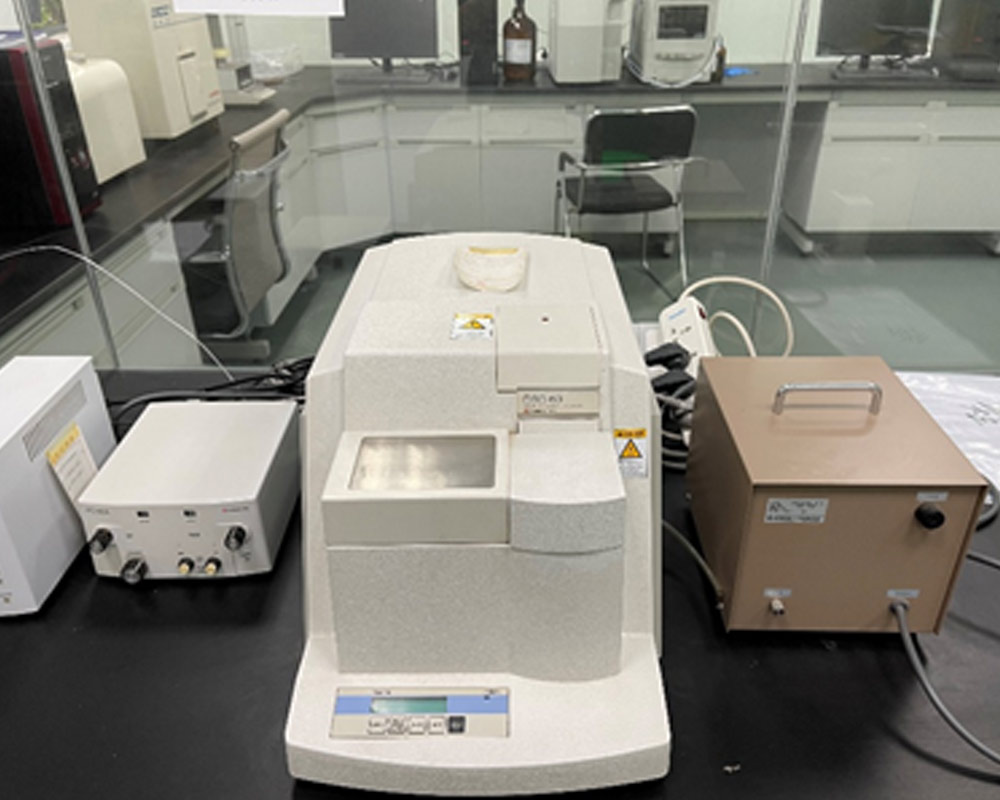

Differential Scanning Calorimeter in Chongqing Laboratory

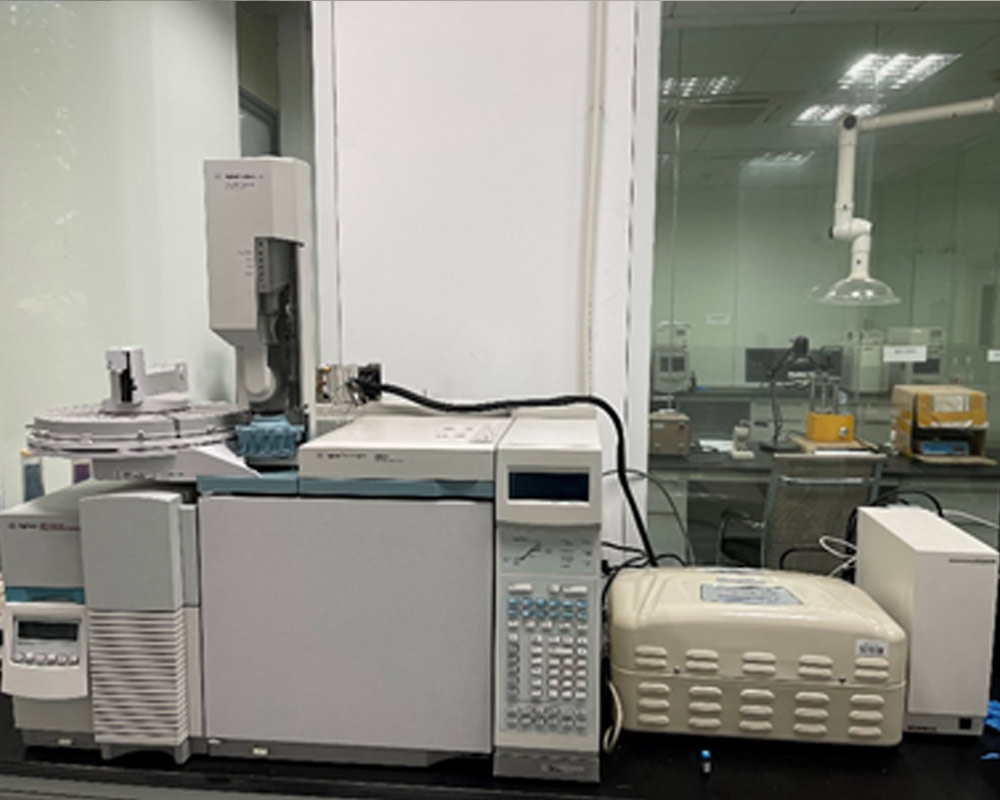

Gas Chromatography-Mass Spectrometry Instrument