What is an adhesion promoter?

With the development of modern coating industry, the types of substrates are becoming more and more diversified, and various new substrates are being applied. Consequently, adhesion problems caused by weak affinity between the coating film and the substrate are also increasing, especially for some low-polarity, low-surface tension, or high-crystallinity substrates, such as polyolefins, polyamides, etc. Conventional methods to improve adhesion mainly include surface treatment of the substrate or adding adhesion promoters.

Adhesion promoters are those additives that, when added to coatings, can greatly enhance the bonding force of the coatings to the substrate. Due to the wide variety of coating resins and substrates, there are various types of adhesion promoters in actual application systems.

Mechanism of action

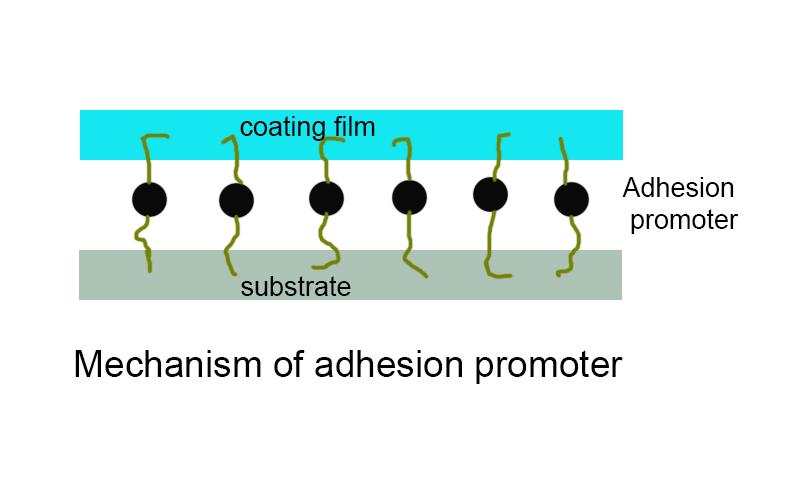

From the perspective of the mechanism of action, all adhesion promoters work by forming a bridging structure between the resin and the substrate to achieve the purpose of improving adhesion, as shown in the figure. The reason why a compound can be used as an adhesion promoter in a certain system is that in the corresponding system, the compound can spontaneously migrate to the surface where the coating film and the substrate bond, and then simultaneously generate strong interactions with both the coating film and the substrate at the interface, thus playing a bridging role between the coating film and the substrate.

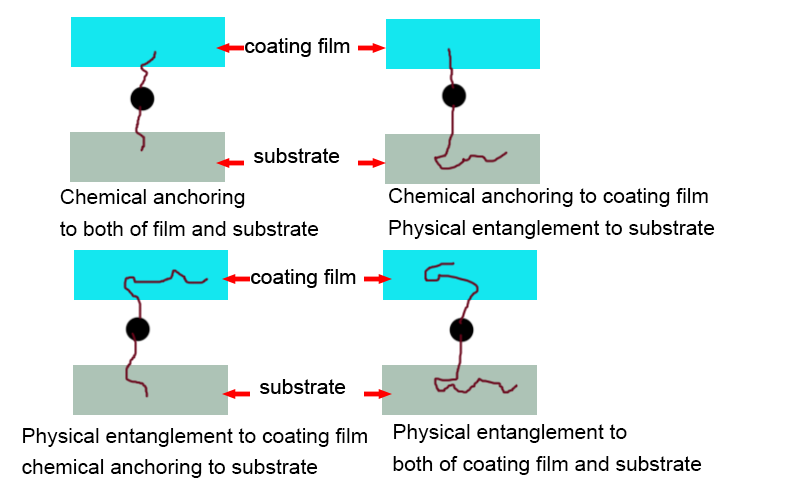

From the perspective of physical chemistry, the interaction forces between the adhesion promoter and the coating film or the substrate can be either chemical bond anchoring forces or van der Waals forces formed by the mutual entanglement of polymer chain segments. Which specific method the adhesion promoter uses to interact with the coating film or substrate mainly depends on the chemical composition of the coating resin and the substrate.

According to the different anchoring methods of adhesion promoters with coating resins or substrates, adhesion promoters can be summarized into the following four modes of action:

-

Chemical anchoring with the coating film and chemical anchoring with the substrate.

-

Chemical anchoring with the coating film and physical entanglement with the substrate.

-

Physical entanglement with the coating film and chemical anchoring with the substrate.

-

Physical entanglement with the coating film and physical entanglement with the substrate.