Amino baking paint is a commonly used industrial coating, with waterborne amino baking paint being a prominent variant. Waterborne amino baking paint offers a range of advantages, including a hard and resilient film, strong adhesion to metal substrates, excellent mechanical properties, resistance to contamination, resistance to oil and grease, tolerance to certain levels of acidity and alkalinity, and resistance to washing. Utilizing water as the solvent, it exhibits features such as non-flammability and non-explosiveness.

As the regulations on Volatile Organic Compounds (VOC) for conventional solvent-based coatings become increasingly stringent, environmentally friendly coatings are gaining significant attention. The waterborne conversion of amino baking paints has found widespread applications in industries such as hardware, bicycles, and electric vehicles for baking paint processes. Notably, the performance of waterborne amino baking paint largely meets the requirements of conventional solvent-based amino baking paint.

In order to better collaborate with our partners in the development of waterborne amino baking paints, DCA Additive Application Laboratory has undertaken various experiments and trials in this field.

1.The fomulation

| Raw materials | Dosage(%) | Noted | Process |

| Water | 10-15 | Grind | |

| DCA-31768 | 0.6-1 | Dispersing Agent | |

| DCA-31700 | 1-1.2 | Dispersing Agent | |

| Diacetone Alcohol | 5 | ||

| Phthalocyanine blue | 1.5-1.7 | ||

| DCA-31357 | 0.1 | Silicone Leveling agent | |

| DCA-31376 | 0.3-0.5 | Substrate wetting agent | |

| Barium sulfate | 10-15 | ||

| DCA-31471 | 0.4-0.5 | Defoamer | |

| titanium dioxide | 3-5 | ||

| DCA-31281 | 0.5 | Silicone Free Leveling Agent | |

| Iron Blue | 1.4-1.9 | ||

| Medium Yellow | 0.2-0.4 | ||

| DCA-31912 | 0.3-0.5 | Rheology Modifier | |

| DCA-31900 | 3 | Amine neutralizer | |

| 3958 | 40-45 | Water borne resin | Paint Mixing |

| 325 | 6-9 | Amine resin | |

| DCA-31488 | 0.2-0.4 | Defoamer | |

| Bentonite | 0.1 | ||

| DCA-31971 | 0.5-0.8 | Anti flush rust agent | |

| DCA-31922 | 0.2-0.3 | Rheology Modifier | |

| Water | 8-10 | ||

| Tech-31753 | 0.5-1 | Adhesion Promoter |

| Raw materials | Dosage(%) | Noted | Process |

| Water | 10-13 | Grinding | |

| DCA-31281 | 0.5 | Silicone Free Leveling Agent | |

| Methyl ether | 2-6 | ||

| Butyl ether | 1-3 | ||

| DCA-31376 | 0.3-0.4 | Substrate wetting agent | |

| Diacetone Alcohol | 2-4 | ||

| DCA-31357 | 0.1-0.2 | Silicone Leveing Agent | |

| DCA-31471 | 0.4-0.6 | Defomaer | |

| E65 | 0.1 | Hydrophobic gas silicon | |

| Carbon Black | 1 | Shanghai Jiaohua Limited Company | |

| Tech-31665 | 1-1.2 | Dispersing Agent | |

| Barium sulfate | 1-1.2 | ||

| 3KB80B | 45-50 | Tod resin | Paint Fixing |

| Triethylamine | 2 | ||

| DCA-31488 | 0.3-0.5 | Defomaer | |

| AMP-95 | 0.5-1 | ||

| 325 | 0.5-1 | Amine resin | |

| DCA-31922 | 0.2-0.4 | Leveling Agent | |

| Water | 8-10 |

2.The test result

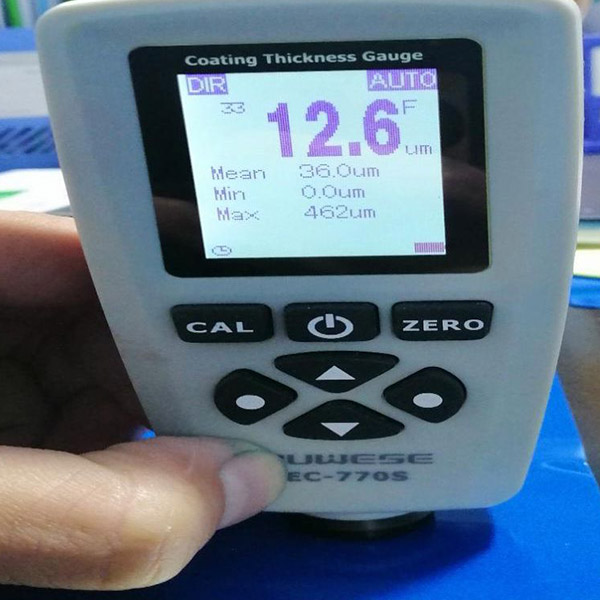

Thickness 12.6 um

Positive and negative impact 100cm – no cracking or detachment

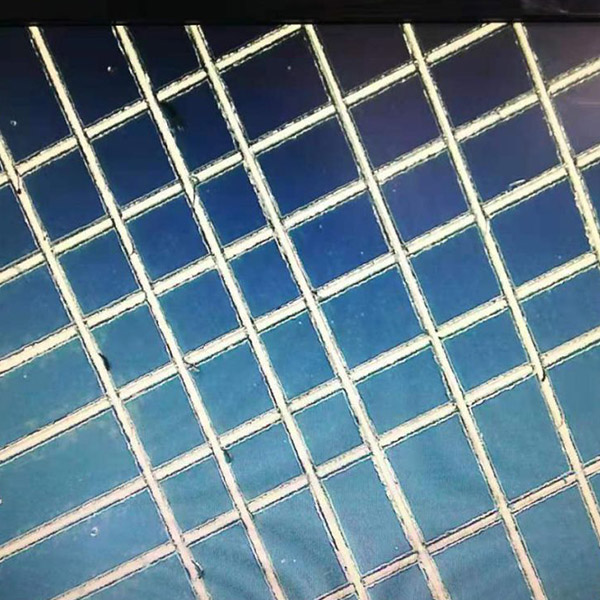

Adhesion grid test – no peeling at the grid edge

Black paint adhesion test

Reflection test- Clear reflection

Curved surface spraying without sagging

Performance test results

| Dry film thickness | 10-15um | Gross | Up 90 |

| Baking temperature | 130 | Hardness | 3H |

| Pre Leveling | 10 minute | Positive and negative impact | 100cm |

| Baking Time | 20-30 minute | Adhesion Promoter | Grade 0 |

3.The additves what we used in the formula as following

Deco Chemical is a professional paint additives manufacturer, ranking among the top three in the paint additives industry in China. We are currently seeking importers or distributors in your country and are also open to customizing specialty paint additives for specific applications. Let’s collaborate to develop the market together.