Water-Based Epoxy Floor Coating Features:

- Sustainability: Water-based epoxy floor coatings are at the forefront of eco-friendly solutions, boasting low carbon emissions and reduced environmental impact.

- Versatility: From residential spaces to bustling commercial establishments, water-based coatings adapt seamlessly, providing a durable and stylish finish.

- Low Odor Profile: Say goodbye to strong solvent odors; water-based coatings offer a fresh, low-odor alternative without compromising on performance.

Places to Use Water-Based Epoxy Floor Coating:

- Residential Spaces: Transform garages, basements, and living areas with water-based epoxy coatings that deliver both style and durability.

- Commercial Establishments: Enhance high-traffic areas in hospitals, shopping malls, and offices with coatings that stand up to wear while maintaining a pristine appearance.

- Eco-Conscious Environments: Ideal for spaces where strong odors are unwelcome, water-based coatings shine in settings where environmental awareness takes center stage.

In the age of sustainability, water-based epoxy floor coatings embody progress. Their ascendancy represents a pivotal step towards coatings that prioritize both performance and the planet. As the demand continues to soar, the tangible benefits and versatile applications of these coatings underscore their pivotal role in shaping a greener future within the coatings landscape.

In order to meet the market demands and cater to customer needs, DCA Application Center have been made in the development of waterborne epoxy floor coatings for reference.

1.The fomulation

| Top coat reference formula A component | ||

| Raw materials | Dosage(%) | Noted |

| Water | 14 | Pre dispersing |

| DCA-9133W | 0.3 | Rheology Modifier |

| DCA-287 | 0.2 | Wetting agent |

| DCA-9522 | 0.4 | Dispersing agent |

| DCA-9491 | 1.2 | Dispersing agent |

| DCA-1437 | 0.2 | Silicone Leveling Agent |

| DCA-382W | 0.3 | Silicone Antiform |

| Phthalocyanine Green | 6 | |

| Titanium Dioxide | 6 | Rutile Type |

| Talcum Powder | 10 | |

| Barium Sulfate | 20 | |

| Propylene Glycol Methyl Ether | 3 | |

| Water | 8 | Above grinding together |

| DCA-8187 | 25 | Curing Agent |

| DCA-4901 | 0.2 | Silicone Antiform |

| DCA-2901 | 0.4 | Silicone Free leveling agent |

| Water | 4.8 | |

| Total | 100 | |

| Top coat reference formula B component | ||

| Raw materials | Dosage(%) | Noted |

| 128 | 21.25 | Epoxy Resin |

| AGE | 3.75 | Active diluent |

| Total | 25 | |

| The ratio of topcoat A to resin B is 4:1 | ||

| Reference formula for intermediate coating | ||

| Raw materials | Dosage(%) | Noted |

| 128 | 10.71 | Epoxy Resin |

| DCA-8186 | 5.36 | Curing Agent |

| Water | 12.5 | |

| White Cement | 21.43 | |

| Quartz sand | 50 | 150/100um each half |

| Total | 100 | |

| Primer reference formula | ||

| Raw materials | Dosage(%) | Noted |

| WA-03 | 150 | Junjiang Tech Curing AGENT |

| Water | 150 | |

| DCA-287 | 0.2 | Dispersing agent |

| DCA-3599 | 0.2 | Silicone defoamer |

| 128 | 100 | Epoxy Resin |

2.The paint photos

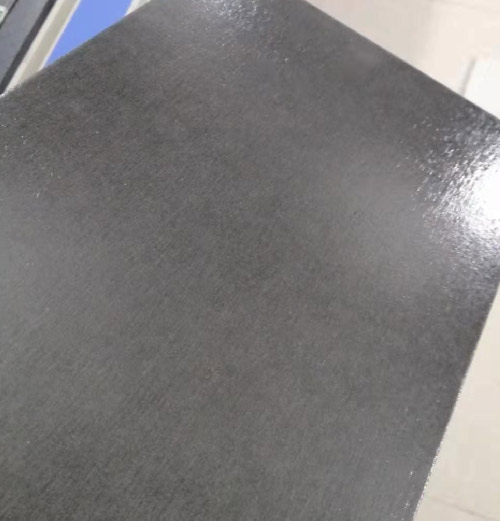

Primer (easy to penetrate, good sealing)

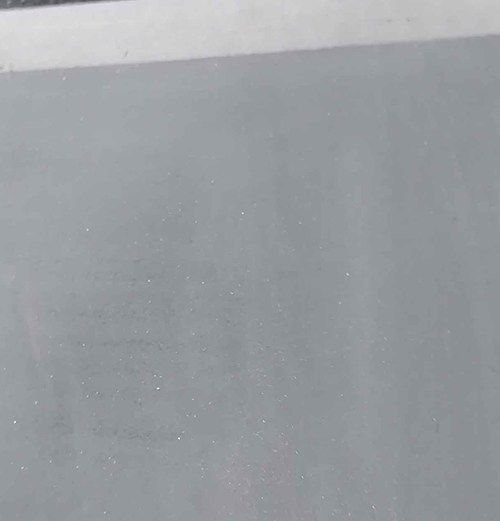

Intermediate coating(easy to apply, non adhering to scraper, overall dense and without bubbles)

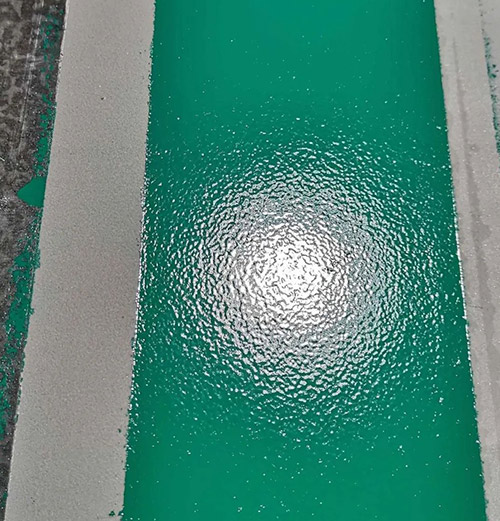

Anti slip water-based epoxy topcoat (with uniform gloss, stable color phase, and good hardness)

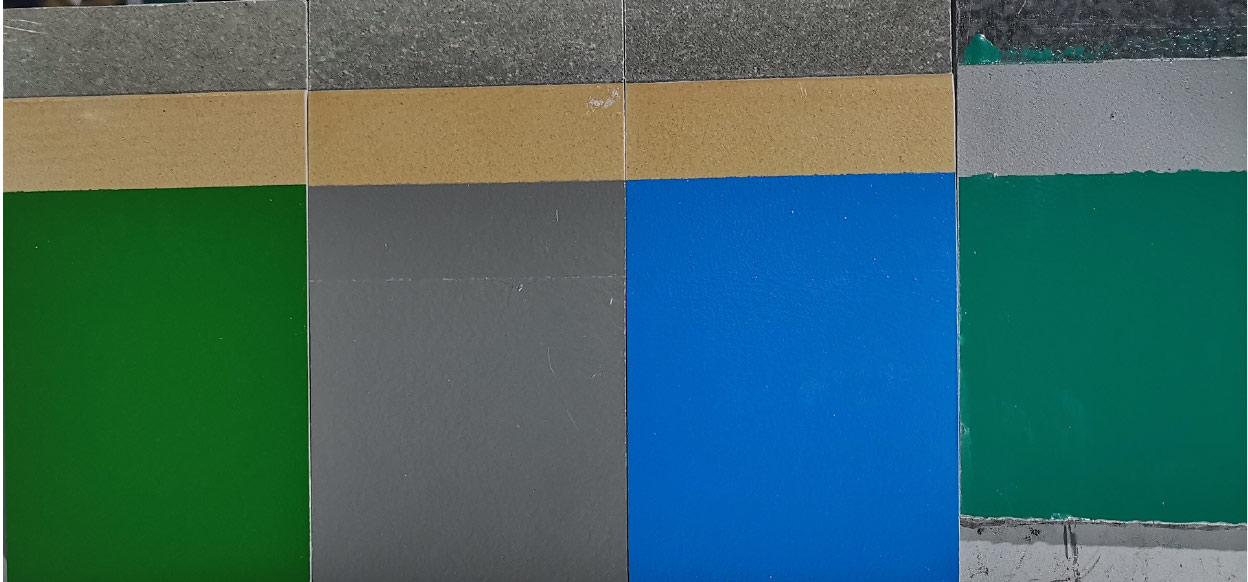

Different color topcoats

3.The additves what we used in the formula as following

Deco Chemical is a professional paint additives manufacturer, ranking among the top three in the paint additives industry in China. We are currently seeking importers or distributors in your country and are also open to customizing specialty paint additives for specific applications. Let’s collaborate to develop the market together.