1.what is hammer pattern paint ?

Hammer paint is often used for decorative purposes, such as on metal surfaces, to give them a unique and visually appealing look. It can be applied to various objects, including furniture, appliances, automotive parts, and other metal surfaces where a hammered metal effect is desired.

The paint is typically available in a variety of colors, allowing you to achieve different metallic finishes, such as silver, gold, bronze, or copper. The textured appearance helps to hide imperfections and surface irregularities, making it a popular choice for DIY projects and refurbishing older items.

When applying hammer paint, it’s important to follow the manufacturer’s instructions regarding surface preparation, application techniques, and drying times for optimal results.

2.How to make water borne hammer pattern paint?

2.1 Please refer to the specific product’s technical data sheet as following

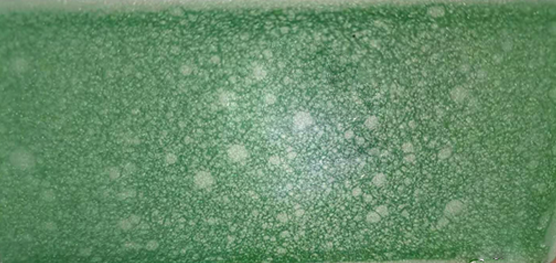

In order to support customer development and evaluation, the Deco Additive Application Center has made some attempts to showcase the patterns created by hammer finish additives for reference.

| Raw material name | Dosage(%) | Noted | Process |

| Titanium dioxide | 4.4 | grind together | |

| Carbon Black C311 | 0.2 | ||

| Iron Oxide Red 130A | 2.6 | ||

| Barium sulfate | 10.5 | ||

| DCA-9022W | 0.4 | Rheology Modifier | |

| DCA-9522 | 1.5 | Dipersing Agent | |

| DCA-9491 | 0.2 | Dipersing Agent | |

| DCA-1056 | 0.1 | Wetting Agent | |

| DCA-276 | 0.1 | Wetting Agent | |

| DCA-371W | 0.3 | Silicone antifoam | |

| DCA-407W | 0.3 | Defoamer | |

| DCA-8100 | 0.1 | Amine Neutralizer | |

| 3958 Resin | 33 | Resin | |

| 325 Resin | 6.5 | Amine Resin | |

| Ethylene glycol butyl ether | 1 | ||

| DCA-2901 | 1 | Silicone Free Leveling agent | |

| Water | 17 | ||

| DCA-1491 | 0.5 | Hammer pattern agent | |

| Silver Powder | 2+2 | 20um+30um | Stiring and dispersing |

| propylene glycol methyl ether | 2 | ||

| DCA-1056 | 0.1 | Wetting Agent | |

| Water | 5 | ||

| DCA-60701 | 0.1 | Dipersing Agent | |

| DCA-9421 | 0.1 | Silver direction arrangement agent | |

| 3958Resin | 9 | Resin | |

| Total | 100 |

| Raw material name | Dosage(%) | Noted | Process |

| Art Green | 10.5 | ||

| Titanium Dioxide | 1.5 | ||

| Barium sulfate | 8 | ||

| DCA-9022W | 0.4 | Rheology modifier | |

| DCA-9522 | 1.5 | Dipersing agent | |

| DCA-1056 | 0.1 | Wetting agent | |

| DCA-276 | 0.1 | Wetting agent | |

| DCA-371W | 0.3 | Silicon antifoam | |

| DCA-407W | 0.3 | Defoamer | |

| DCA-8100 | 0.1 | Amine Neutralizer | Grind together |

| 3958 Resin | 33 | Resin | |

| 325 Resin | 6.5 | Amine Resin | |

| Ethylene glycol butyl ether | 1 | ||

| DCA-2901 | 1 | Silicone free leveling agent | |

| water | 15 | ||

| DCA-1491 | 0.5 | Hammer pattern agent | |

| Silver Powder | 2+2 | 20um+30um | |

| propylene glycol methyl ether | 2 | ||

| DCA-1056 | 0.1 | Wetting agent | Stir |

| water | 5 | Dispersing | |

| DCA-60701 | 0.1 | Dipersing agent | |

| DCA-9421 | 0.1 | Silver direction arrangement agent | |

| 3958 Resin | 9 | Resin | |

| Total | 100 |

2.2 The principle of hammer finish additives is based on their incompatibility with the system

In waterborne hammer pattern paint, the unique textured appearance is achieved through the use of hammer finish additives. These additives are incorporated into the paint formulation and work based on their incompatibility with the rest of the paint system. When the paint is applied and dries, these additives separate or phase out from the paint film, creating the textured or hammered effect. The incompatibility of these additives with the rest of the system leads to the formation of distinct patterns that resemble hammered metal.

2.3 Factors such as temperature, humidity, spraying equipment, spraying process, and viscosity have a significant impact on hammer finish paint

Various factors can influence the outcome and quality of waterborne hammer pattern paint. Here we make test through different viscosities.

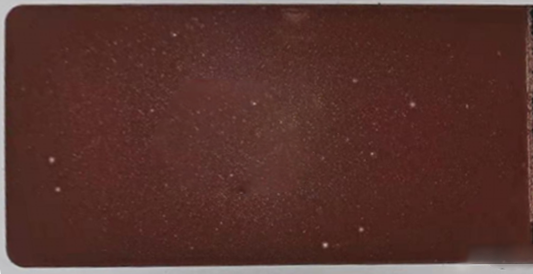

The viscosity is too higher

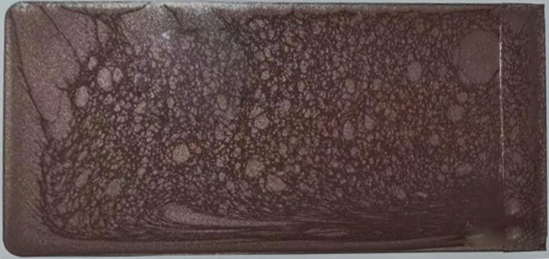

The viscosity is too lower

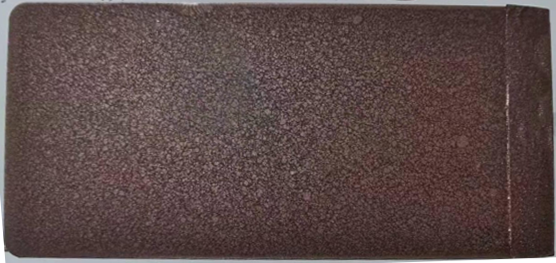

The viscosity is suitable

In the above experiment, controlling the viscosity of the hammer finish paint achieved better patterns. If the viscosity is too high, the hammer finish additive cannot migrate to the surface of the coating, resulting in no pattern formation. If the viscosity is too low, the hammer finish additive will re-aggregate on the surface of the coating, leading to uneven patterns. The appropriate viscosity allows the hammer finish additive to migrate to the surface of the coating without re-aggregation, resulting in uniform patterns.

Deco Chemical is a professional paint additives manufacturer, ranking among the top three in the paint additives industry in China. We are currently seeking importers or distributors in your country and are also open to customizing specialty paint additives for specific applications. Let’s collaborate to develop the market together.