Are you facing challenges in creating paints that can withstand high-temperature applications and provide effective metal protection?

Many industries, such as those dealing with fireplaces, steel plant blast furnaces, heat exchangers, hot stoves, chimneys, exhaust pipes, automotive components, ovens, thermal pipelines, and various high-temperature components, require top-notch metal corrosion protection. However, traditional coatings often fall short, especially for long-term use above 300°C. It is critical to find a solution that ensures protective coatings do not crack, peel, or lose their luster under high-temperature conditions, guaranteeing the most effective metal protection.

How can you enhance your paint formulations for high-temperature applications?

The DCA Additive Application Center has the perfect solution to elevate your paint products. Through extensive research and experimentation, we have developed high-temperature resistant additives that will revolutionize your paint manufacturing process. By carefully selecting organic silicone emulsions and combining them with high-temperature-resistant fillers, we have created a cutting-edge paint formulation capable of withstanding temperatures up to 500°C for an extended period

As our customer requested we have do some test in our laboratory, here with the formula

| Color paste reference formula | ||

| Raw materials | Dosage(%) | Noted |

| Copper chrome black | 12 | |

| Low melting point glass powder | 38 | Anmi Anywhere |

| Ceramic clay | 5 | |

| Barium sulfate | 2 | |

| Water | 39.6 | |

| DCA-509 | 1.5 | Dispersing agent |

| E-30 | 0.8 | Hydrophilic aerosilicon |

| DCA-382W | 0.3 | Defoaming agent |

| Bentonite | 0.2 | |

| DCA-287 | 0.1 | Wetting agent |

| Total | 100 | |

Thanks for Anmi Anywhere offer low melting point glass powder.

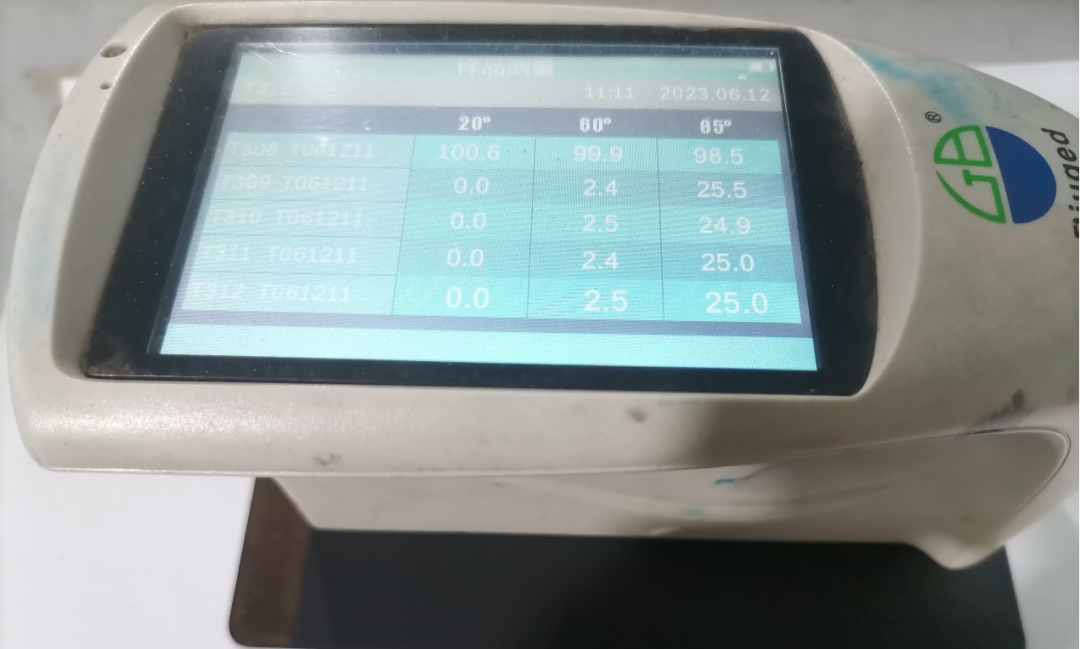

The test result as following

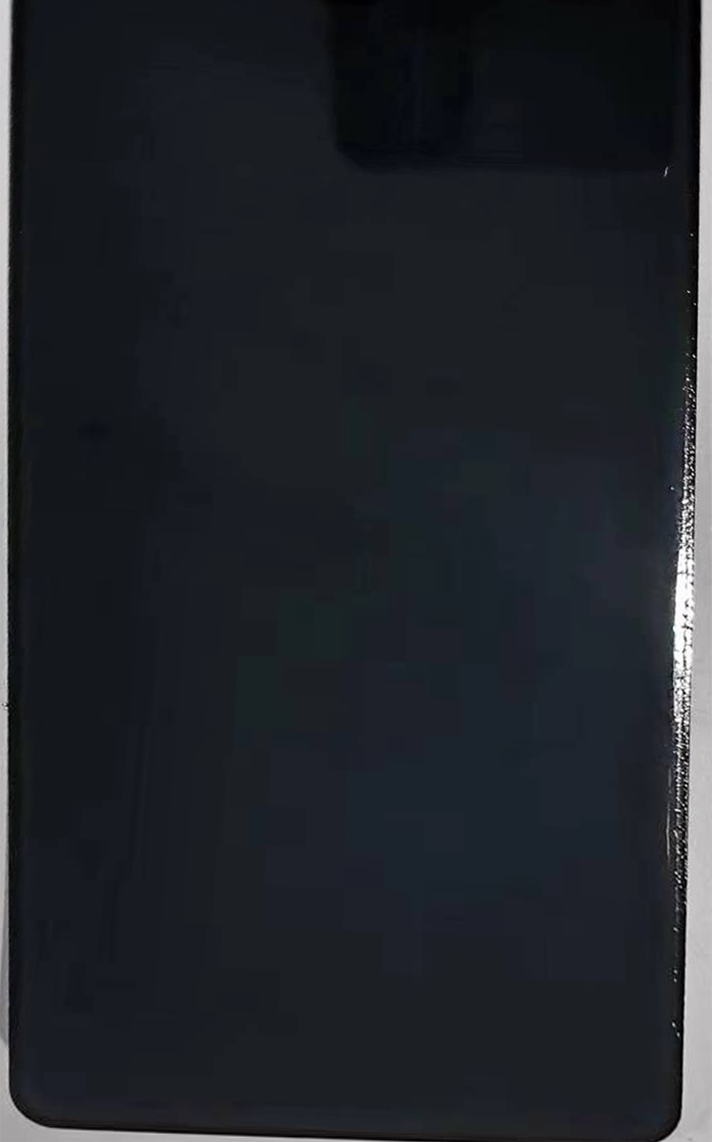

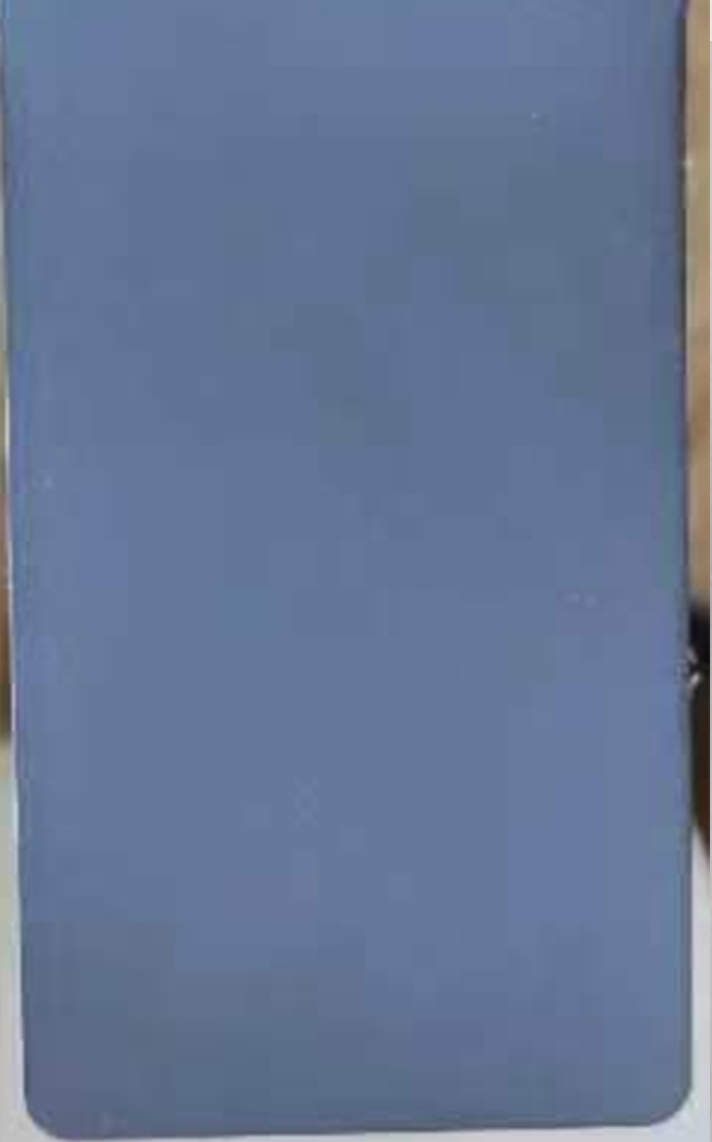

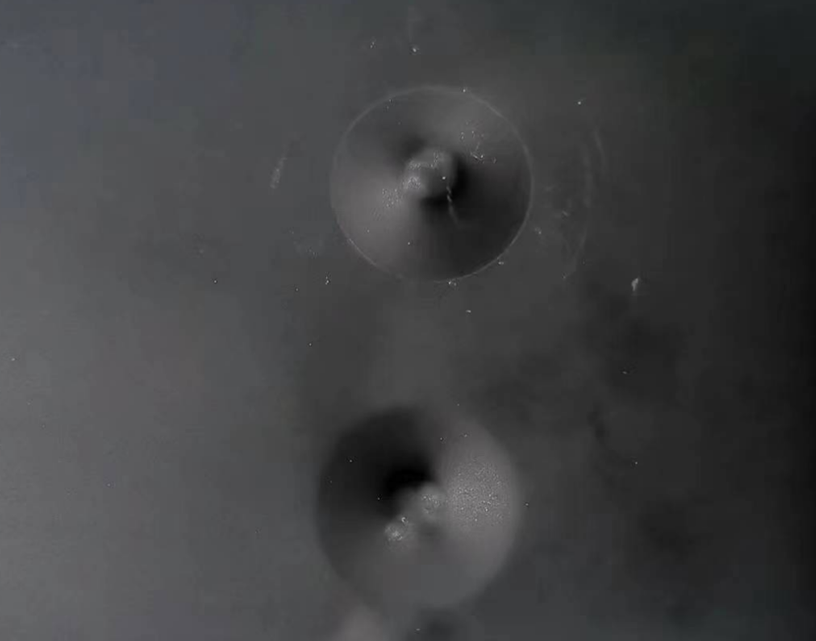

Black paint film

Dry film

500 degree heat 90 minutes

Gross test

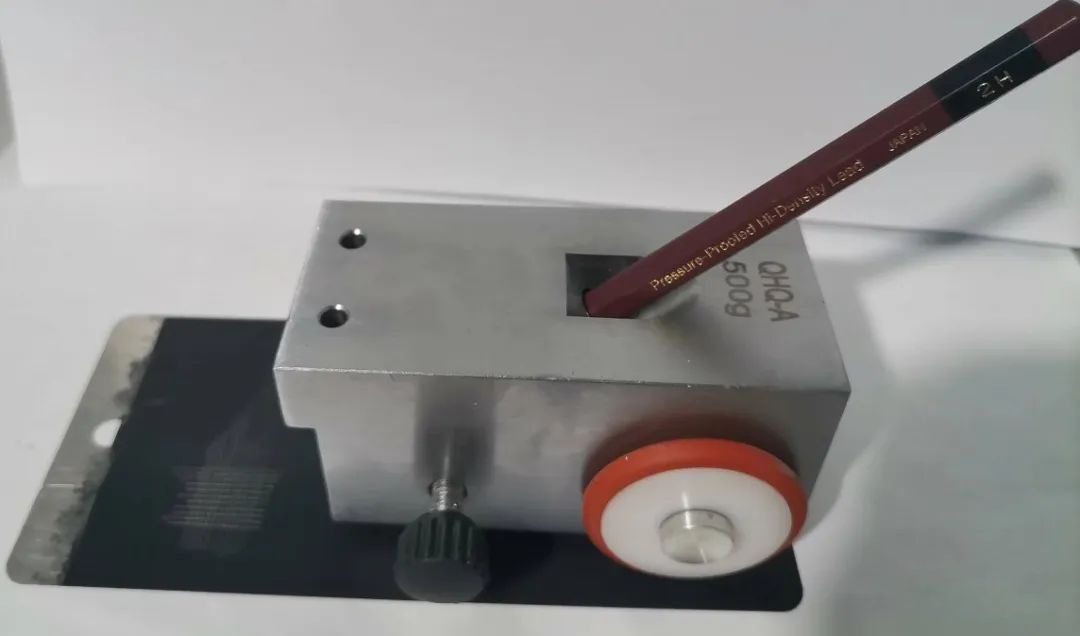

Hardness test

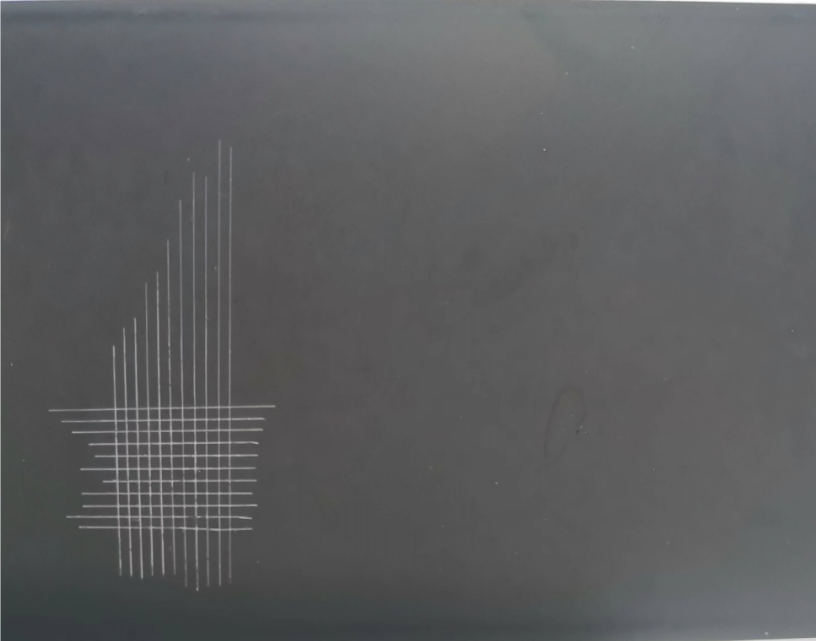

Coating adhesion test

Impact testing

The additives what we used in the formula

Deco Chemical is a professional paint additives manufacturer, ranking among the top three in the paint additives industry in China. We are currently seeking importers or distributors in your country and are also open to customizing specialty paint additives for specific applications. Let’s collaborate to develop the market together.