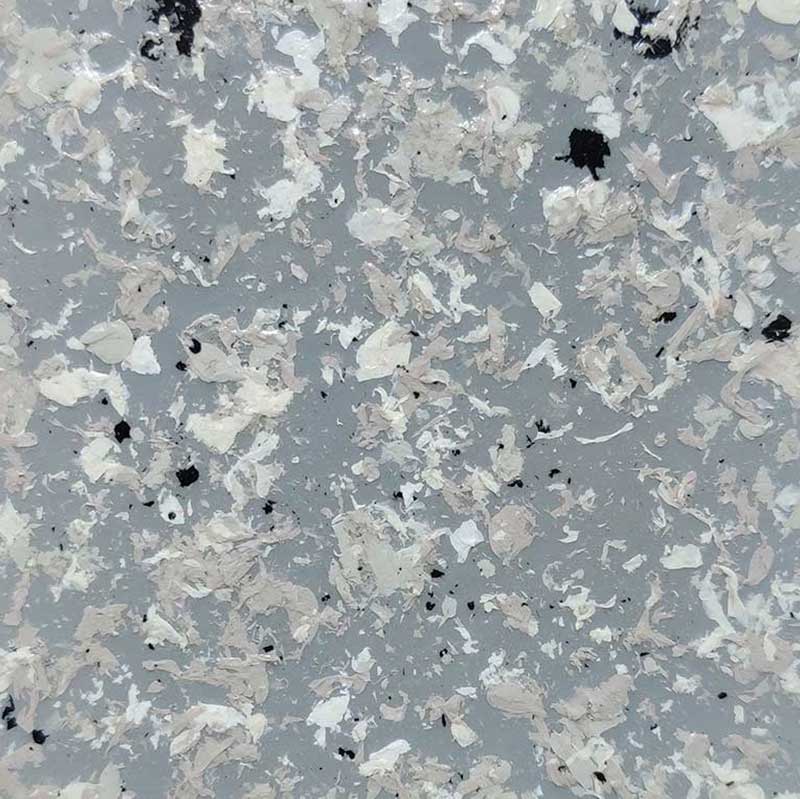

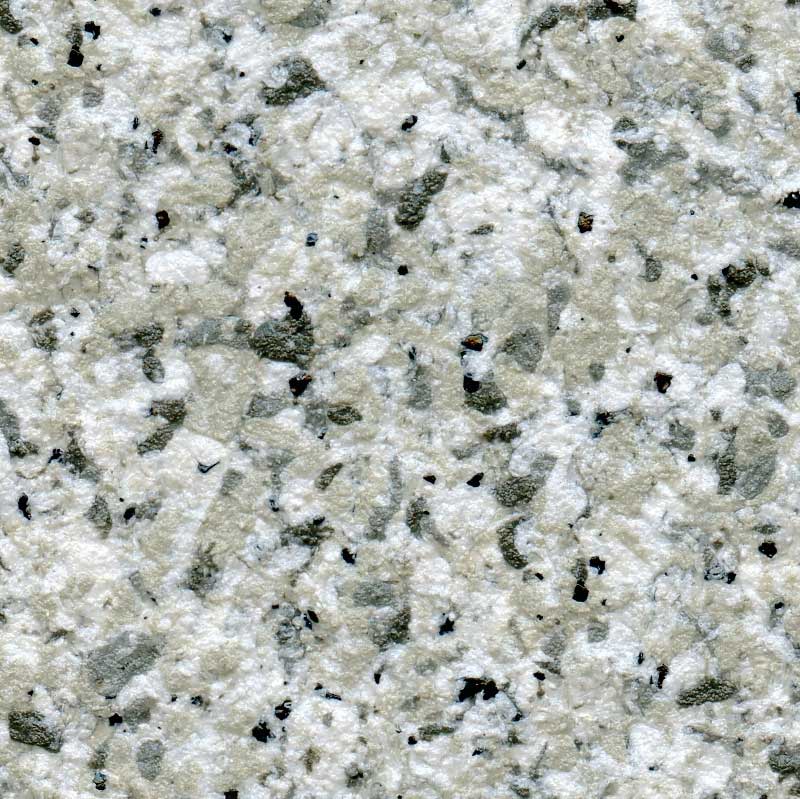

1. What is Imitation Stone Paint?

Imitation stone paint is a thick exterior wall decorative coating that closely resembles the decorative effect of marble and granite. It is primarily made using various colors of natural stone powder, often used to create imitation stone effects on building exteriors, hence also known as liquid stone.

Buildings decorated with imitation stone paint exhibit natural and authentic colors, imparting an elegant, harmonious, and dignified beauty. It is suitable for both interior and exterior decoration of various types of buildings. Particularly on curved buildings, its use achieves a vivid, lifelike effect, returning to nature.

3. Imitation Stone Paint Construction Process and Methods

Construction Process

Before starting the imitation stone paint application, some preparatory work is needed. First, ensure the construction surface is clean, smooth, and free from all impurities and dust. Next, if necessary, sand and repair the wall to ensure a smooth surface. Finally, choose the suitable imitation stone paint color and mix it as required.

3.1 Primer Application

Before applying imitation stone paint, it’s necessary to apply a primer. The purpose of the primer is to enhance the adhesion of the base wall and improve the color performance of the imitation stone paint. Choose suitable tools for primer application and follow the construction instructions to ensure even and consistent application.

3.2 Imitation Stone Paint Spraying

After the primer dries, proceed with the spraying of the imitation stone paint. Select appropriate spraying tools and methods and follow the construction instructions. When spraying, maintain a certain distance and angle to ensure an even effect and avoid patchiness or uneven color density.

3.3 Crack Treatment

After the application of imitation stone paint, if necessary, perform grid segmentation. This process can enhance the texture and layers of the imitation stone paint. Choose suitable tools and methods for grid segmentation and follow the instructions, paying attention to control the size and shape of the cracks.

3.4 Protective Layer Application

Finally, after the imitation stone paint application, apply a protective layer. This layer increases the durability and stain resistance of the imitation stone paint. Choose suitable tools for the application of the protective layer, following the instructions to ensure an even and consistent coat.

Construction Considerations

When applying imitation stone paint, pay attention to the following:

- Ensure a well-ventilated construction environment to avoid dust and odors affecting the quality of the work.

- Follow construction instructions to avoid issues such as coating peeling or cracking.

- Control the thickness of the spray to avoid overly thick or thin applications that compromise the quality.

- Clean the construction tools promptly after completion to avoid difficulties in cleaning once they dry.

Imitation stone paint process table

| Process Step | Number of Coats | Coating Amount (kg/m2) | Drying Time (h) | Construction Tools | Remarks |

| Surface Treatment | Clean debris and dust off the surface before construction. Proceed after the surface dries. | ||||

| Leveling Putty | 2 | 2-3 | 48 | Trowel, Scraper, Ruler | Level the surface. |

| Smoothing Putty | 1 | 1 | 48 | Trowel, Scraper, Ruler | Level the surface. |

| Sealing Primer | 1 | 0.1-0.125 | 12 | Roller, Wool Brush, Spray Gun | Alkali-resistant and solidifying. |

| Marking Grid Joints | Mark grid joints as per design, using colored tape for protection. | ||||

| Colored Mid-Coat Paint | 1-2 | 0.2-0.3 | 24 | Spray Gun | Main base color. |

| Waterborne Color Spots | 1-2 | 0.2-0.5 | 24 | Specialized Spray Equipment | Imitation stone effect. |

| Topcoat Application | 1-2 | 0.1-0.125 | 12 | Spray Gun | Weather-resistant protection. |

5. The effect picture of the customer using imitation stone paint