The hardness and impact resistance of water-based paint need to be balanced in terms of performance. This is because they have different importance and functions in coating applications.

1.Introduction hardness and impact resistance

Water-based paint typically utilizes polymer resins, such as acrylic resin, as the base. When balancing hardness and impact resistance, paint manufacturers need to consider the characteristics of the resin system and the formulation of additives. Increasing the crosslink density of the resin and the dosage of hardeners can enhance the hardness of the coating but may reduce its impact resistance. Conversely, the use of plasticizers or toughening agents can improve impact resistance while potentially lowering hardness.

In summary, balancing the hardness and impact resistance of water-based paint is done to achieve optimal coating performance and protection in different application scenarios.

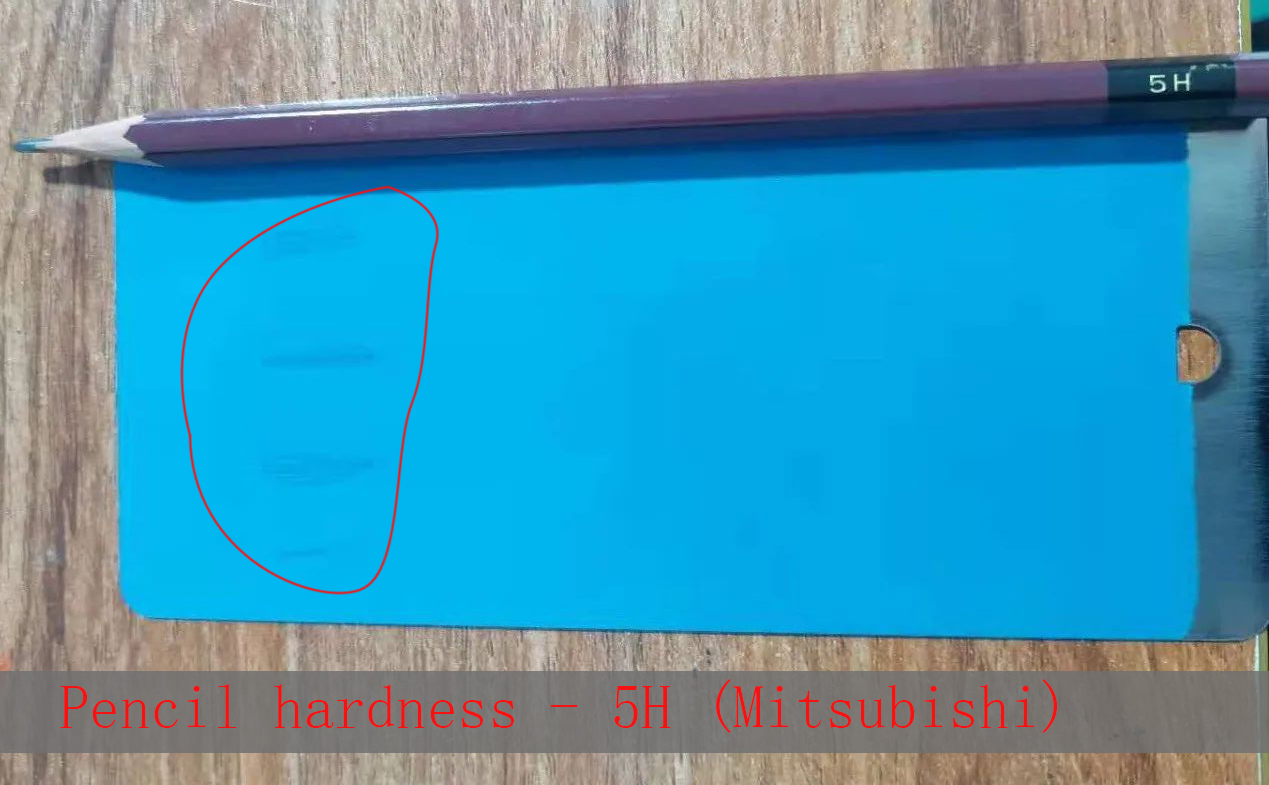

The typical hardness of conventional water-based amino baking paint film ranges from 2H to 4H. However, in certain specific application environments, water-based paint may require a hardness of up to 5H and an impact resistance of 50cm without cracking. To meet customer requirements, the DCA Additive Application Center has developed a water-based baking paint formulation (180°C) that achieves high hardness and impact resistance using existing market raw materials.

2.The fomulation

| High hardness water-based blue amino baking paint | ||

| Raw materials | Dosage(%) | Noted |

| 8303-1-1 | 40-45 | Xiance water borne resin |

| N,N-Dimethylethanolamine | 3-5 | Amine neutralizer |

| DCA-1058 | 0.2 | Wetting agent |

| DCA-3488 | 0.3-0.5 | Defoamer |

| DCA-2901 | 0.5 | Silicone Free Leveling Agent |

| Ethylene glycol butyl ether | 5-8 | |

| Dipropylene glycol butyl ether | 3-5 | |

| Blue color paste | 30 | |

| Amino resin | 6.9 | yb1653 |

| DCA-6220 | 0.2 | Rheology modifier |

| Water | 5-10 | |

| Water Based Blue Paste | ||

| Raw materials | Dosage(%) | Noted |

| Water Borne Blue Paste | 23.7 | |

| DCA-9491 | 6 | Dispersant |

| DCA-9522 | 3.5 | Dispersant |

| Titanium dioxide | 15 | |

| DCA-276 | 0.6 | Wetting Agent |

| Barium Salfate | 42 | |

| DCA-1437 | 0.5 | Silicone Leveling Agent |

| DCA-8095 | 0.5 | Amine neutralizer |

| Phthalocyanine blue | 6 | Phthalocyanine blue |

| DCA-493 | 0.6 | Silicone Defoaming Agent |

| DCA-9058 | 1 | Nano magnesium aluminum silicate |

| K9N | 0.1 | Bactericide |

| Middle chrome yellow | 0.5 | |

| Total | 100 | |

| Water Based Varnish | ||

| Raw materials | Dosage(%) | Noted |

| 8303-1 Resin | 50 | Xiance water borne resin |

| N,N-Dimethylethanolamine | 3-5 | |

| DCA-1058 | 0.2 | Wetting Agent |

| DCA-3488 | 0.3-0.5 | Silicone Defoaming Agent |

| DCA-1437 | 0.1-0.2 | Silicone Leveling Agent |

| Ethylene glycol butyl ether | 5-8 | |

| Dipropylene glycol butyl ether | 3-5 | |

| Amino Resin | 8.4 | yb1653 |

| deionized water | 15-18 | |

Adhesion Test

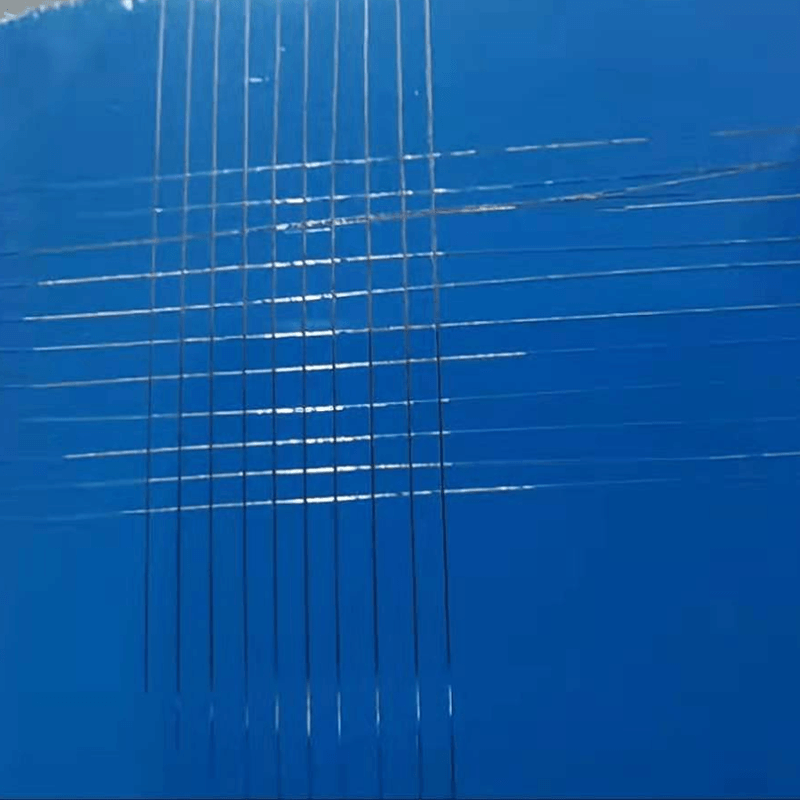

Impact Resistance Test

Deco Chemical is a professional paint additives manufacturer, ranking among the top three in the paint additives industry in China. We are currently seeking importers or distributors in your country and are also open to customizing specialty paint additives for specific applications. Let’s collaborate to develop the market together.