How to aovid pinholes in coating?

In the realm of paint application and surface finishing, pinholes represent a small yet significant challenge that can affect the overall quality and durability of the paint film. But what exactly are pinholes, and why do they form? Let’s dive deeper into this phenomenon, understand its implications, and explore effective strategies to mitigate it.

1.Pinhole Definition

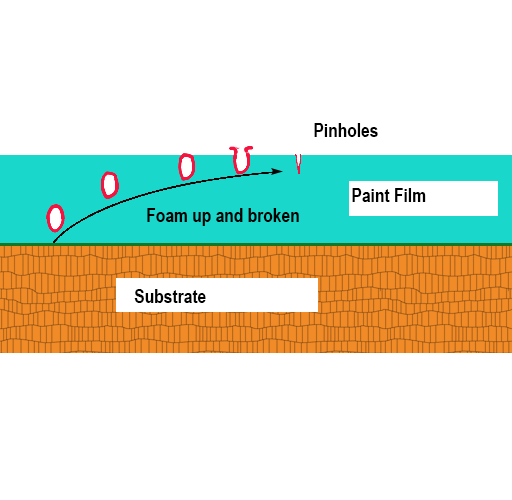

During the drying process of a paint film, bubbles that form and subsequently burst can leave behind small holes if the paint film does not have sufficient time to level out. These small holes are known as pinholes. They are not just a cosmetic issue but can also compromise the integrity and protective qualities of the paint film.

2.Damage Caused by Pinholes

Pinholes can significantly mar the appearance of a paint film, making it difficult to pass visual inspection. More critically, they can impair the film’s sealing ability, leading to a decrease in its resistance qualities, such as water resistance and corrosion resistance. This can shorten the lifespan of the paint film and necessitate premature maintenance or repair.

3.

Several factors can contribute to the formation of pinholes, including:

- Moisture Interaction: The presence of moisture in substrates, paint materials, or diluents is a primary contributor. Moisture can interact with two-component polyurethane curing agents, resulting in the production of CO2 gas. This chemical reaction is a direct pathway to the formation of pinholes, undermining the paint’s smooth finish.

- Substrate Condition: Rough substrates characterized by pores can adversely affect the paint application process, leading to uneven surfaces that are prone to pinhole formation. Ensuring substrate smoothness is essential for preventing this issue.

- Solvent and Drying Agent Usage: The utilization of excessive amounts of low-boiling-point solvents or drying agents in the paint composition can exacerbate pinhole formation. These components can evaporate too quickly, leaving behind imperfections in the paint film.

- Thickness of Paint Film: Applying the paint film too thickly is another critical factor. Thick applications can lead to surface drying and internal solvent evaporation before the paint has properly settled, resulting in pinholes. Achieving an optimal thickness is key to avoiding this problem.

- Rapid Reaction in High-Temperature Baking Paint: The rapid reaction of paint under high-temperature baking conditions can also contribute to pinhole formation. This issue can be mitigated by adding an appropriate amount of butanol, which helps in controlling the reaction rate and maintaining the quality of the paint finish.

4. Solutions to Pinhole Problems

- djusting Evaporation Rates: A fundamental strategy is to fine-tune the evaporation rate of mixed solvents. This adjustment aims to maintain a low viscosity at the paint film’s surface long enough for bubbles to escape and the surface to level out before it becomes too viscous. This approach is crucial for preventing pinhole formation from the outset.

- Optimizing Coating Thickness: Reducing both the thickness of each coating layer and the overall thickness of the paint film is vital. Thinner layers minimize the risk of pinhole formation, underscoring the importance of precision in paint application.

- Ensuring Proper Leveling Time: Allowing adequate leveling time before the baking process is essential. This step ensures that the paint film can settle and even out, further reducing pinhole risks.

- Effective Use of Diluents: Diluents should be used strategically to adjust paint viscosity without introducing factors that could lead to pinhole formation. Proper diluent selection and usage are key to achieving optimal results.

- Maintaining Appropriate Paint Thickness: When spraying, it is critical to maintain a controlled thickness. This precision helps in preventing the conditions that lead to pinholes, emphasizing the need for skilled application techniques.

- Allowing Paint to Settle: Letting paint sit after mixing to allow for bubble dissipation is a simple yet effective preventive measure. This practice can significantly reduce the likelihood of pinholes developing.

- Sealing Putty Layers: Before applying topcoats, it is crucial to seal putty layers properly. This step can serve as an additional barrier against pinhole formation.

- Corrective Measures for Existing Pinholes: In cases where pinholes occur, sanding the paint film down to the base coat, filling in the pinholes, and reapplying the paint is a proven remedy. This method addresses the issue directly, restoring the integrity of the paint film.

Implementing these strategies can significantly reduce the incidence of pinholes, ensuring a smoother, more uniform paint finish.

5. Our Suggestions

For more detailed insights into the formation of bubbles in coatings, their impacts, and the differences between anti-foam agents and defoamers, we invite you to visit our resources:

Understanding and addressing the issue of pinholes in paint films is essential for achieving high-quality finishes that stand the test of time. By recognizing the causes and employing effective solutions, manufacturers and applicators can significantly improve the durability and appearance of their painted surfaces.