How to choose defoamer for paint?

The following are some tips how to select the defoamer for paint

- Selecting Paint and Coating Defoamers with Low Volatility and Long-lasting Defoaming Action

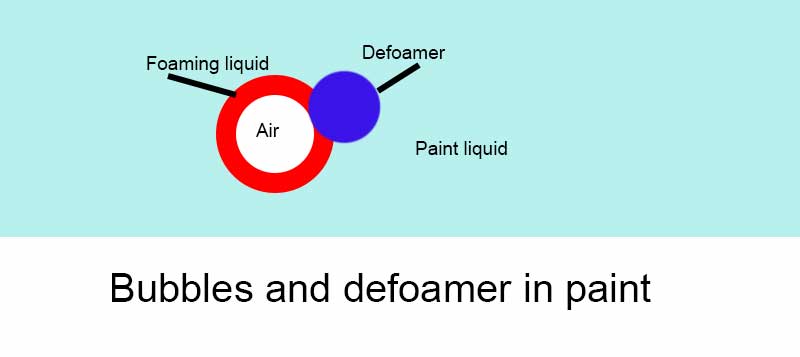

To burst the bubble, the defoamer should concentrate and intensify on the bubble film. If it’s a bubble breaker, it should instantly concentrate and intensify, and for bubble suppression, it should maintain this state consistently.

Thus, the defoamer in the foaming liquid is supersaturated and less volatile, easily accumulating at the gas-liquid interface and concentrating on the foam film to lower the concentration.

For water-based systems, the active components of the defoamer must be strongly hydrophobic and weakly hydrophilic, with an HLB value in the range of 1.5-3 for optimal effect!

2. Determine whether the foaming liquid is water-based or solvent-based

For water-based paints, choose a water-based or silicone defoamer; for the paint industry, typically select an solvent-based defoamer, such as polyether defoamers or polyether-modified silicone defoamers. Besides confirming the defoamer system, compare the addition amounts and reference prices to choose an economical and suitable defoamer product.

3.

Chemical reactions between the foaming liquid and defoamer may produce harmful substances that affect microbial growth or cause the defoamer to lose its effectiveness.

4.

To enable defoamer particles to penetrate and spread on the foam film, the defoamer should have a lower intermolecular force, with its surface tension being lower than that of the foaming agent in the foaming liquid.

5. Paint and Coating Defoamers Must Be Compatible with the Foaming Liquid:

The defoamer should disperse quickly in the foaming liquid to be effective over a wide area. This requires a balance between the speed of foam collapse and foam formation. If the active component of the defoamer is too compatible with the foaming liquid, it may dissolve; if it’s too incompatible, it might be difficult to disperse. Therefore, the defoamer’s active component should have a certain level of compatibility with the foaming liquid, balancing between being too compatible and too incompatible, for better and faster dispersion.

Recommended table for defoamers for different coatings

| Application | Paint Type | Defoamer | Features |

|---|---|---|---|

| Wood Coating | PU clear top coating | DCA-468 | Excellent compatibility,Suitable for UV,UPE and Epoxy system |

| Wood Coating | PU clear top coating | DCA-352 | Excellent compatibility,Rapid defoaming speed |

| Wood Coating | PU clear top coating | DCA-4067 | Very strong defoaming ability,it is crater possiblity should tested before used |

| Wood Coating | PU matting top coating | DCA-463 | Designed for high viscosity system, should test compatibility before used |

| Wood Coating | PU matting top coating | DCA-442 | Designed for high viscosity system, very suitable for primer with high zinc stearate |

| Wood Coating | PU matting top coating | DCA-4067 | Very strong defoaming ability,it is crater possiblity should tested before used |

| Wood Coating | PU primer | DCA-442 | Designed for high viscosity system, very suitable for primer with high zinc stearate |

| Wood Coating | PE top coating | DCA-468 | Excellent compatibility,Suitable for UV,UPE and Epoxy system |

| Wood Coating | PE primer | DCA-442 | Designed for high viscosity system, very suitable for primer with high zinc stearate |

| Wood Coating | PE primer | DCA-468 | Excellent compatibility,Suitable for UV,UPE and Epoxy system |

| Wood Coating | NC | DCA-442 | Designed for high viscosity system, very suitable for primer with high zinc stearate |

| Wood Coating | UV | DCA-305 | Excellent compatibility, low possible cause to crater |

| Wood Coating | UV | DCA-320 | Special designed for UV system,low possible to cause crater |

| Plastic Coating | 2K PU | DCA-3199 | Excellent compatibility,Rapic defoaming speed,suitable for UV and Epoxy system |

| Plastic Coating | Thermoplastic acrylate | DCA-3199 | Excellent compatibility,Rapic defoaming speed,suitable for UV and Epoxy system |

| Automative Paint | Top coating | DCA-352 | Excellent compatibility,Rapid defoaming speed |

| Coil Coating/Baking Paint | Polyester Melamine | DCA-442 | Designed for high viscosity system, very suitable for primer with high zinc stearate |

| Coil Coating/Baking Paint | Polyester Melamine | DCA-463 | Designed for high viscosity system, should test compatibility before used |

| Coil Coating/Baking Paint | Acrylate Melamine | DCA-442 | Designed for high viscosity system, very suitable for primer with high zinc stearate |

| Coil Coating/Baking Paint | Acrylate Melamine | DCA-463 | Designed for high viscosity system, should test compatibility before used |

| UV Coating | DCA-409 | High efficiency, suitable for all kinds of solvent system | |

| UV Coating | DCA-305 | Excellent compatibility, low possible cause to crater | |

| UV Coating | DCA-320 | Special designed for UV system,low possible to cause crater | |

| Floor Paint | DCA-418 | High efficeincy,special designed for high viscosity system | |

| Floor Paint | DCA-442 | Designed for high viscosity system, very suitable for primer with high zinc stearate | |

| Floor Paint | DCA-409 | High efficiency, suitable for all kinds of solvent system | |

| Soft-touch Paint | DCA-352 | Excellent compatibility,Rapid defoaming speed | |

| Soft-touch Paint | DCA-4067 | Very strong defoaming ability,it is crater possiblity should tested before used | |

| Heavy Duty Paint | DCA-418 | High efficeincy,special designed for high viscosity system | |

| Heavy Duty Paint | DCA-442 | Designed for high viscosity system, very suitable for primer with high zinc stearate | |

| Color Paste | Solvent-based | DCA-418 | High efficeincy,special designed for high viscosity system |

| BMC,SMC | DCA-463 | Designed for high viscosity system, should test compatibility before used | |

| BMC,SMC | DCA-468 | Excellent compatibility,Suitable for UV,UPE and Epoxy system | |

| BMC,SMC | DCA-436 | High efficeincy,special designed for high viscosity system, the compatibility should be tested before use |

| Application | Defoamer | Features |

|---|---|---|

| PU wood coating | DCA-335W | Good compatibility,low possiblity to cause crater |

| PU wood coating | DCA-382W | High effiency,special designed for high viscosity system |

| Acrylic wood coating | DCA-335W | Good compatibility,low possiblity to cause crater |

| UV wood coating | DCA-335W | Good compatibility,low possiblity to cause crater |

| UV wood coating | DCA-382W | High effiency,special designed for high viscosity system |

| UV wood coating | DCA-4061 | Rapid defoaming speed,easy to disperse,low possiblity to cause crater |

| Plastic paintDCA-335W | DCA-335W | Good compatibility,low possiblity to cause crater |

| Plastic paint | DCA-382W | High effiency,special designed for high viscosity system |

| Plastic paint | DCA-4061 | Rapid defoaming speed,easy to disperse,low possiblity to cause crater |

| Plastic paint | DCA-421 | Rapid defoaming speed,low possiblity to cause crater |

| Automative paint | DCA-215E | Excellent substrate wettingand antiform ability |

| Automative paint | DCA-335W | Good compatibility,low possiblity to cause crater |

| Automative paint | DCA-382W | High effiency,special designed for high viscosity system |

| Automative paint | DCA-4061 | Rapid defoaming speed,easy to disperse,low possiblity to cause crater |

| Automative paint | DCA-421 | Rapid defoaming speed,low possiblity to cause crater |

| Ink | DCA-335W | Good compatibility,low possiblity to cause crater |

| Ink | DCA-382W | High effiency,special designed for high viscosity system |

| InkDCA-4061 | DCA-4061 | Rapid defoaming speed,easy to disperse,low possiblity to cause crater |

| Ink | DCA-361W | Rapid defoaming speed,easy to disperse,low possiblity to cause crater |

| Industry paint | DCA-335W | Good compatibility,low possiblity to cause crater |

| Industry paint | DCA-382W | High effiency,special designed for high viscosity system |

| Industry paint | DCA-4061 | Rapid defoaming speed,easy to disperse,low possiblity to cause crater |

| Floor coating | DCA-335W | Good compatibility,low possiblity to cause crater |

| Floor coating | DCA-382W | High effiency,special designed for high viscosity system |

| Floor coating | DCA-4061 | Rapid defoaming speed,easy to disperse,low possiblity to cause crater |

| Color pasteDCA-335W | DCA-335W | Good compatibility,low possiblity to cause crater |

| Color paste | DCA-382W | High effiency,special designed for high viscosity system |

| Heavy duty | DCA-335W | Good compatibility,low possiblity to cause crater |

| Heavy duty | DCA-382W | High effiency,special designed for high viscosity system |

| Architectural coating | DCA-417W | Special for UV system,excellent for compatibility |

| Leather paint | DCA-335W | Good compatibility,low possiblity to cause crater |

| Leather paint | DCA-382W | High effiency,special designed for high viscosity system |

| Leather paint | DCA-4061 | Rapid defoaming speed,easy to disperse,low possiblity to cause crater |

| Leather paint | DCA-421 | Rapid defoaming speed,low possiblity to cause crater |