How to identify the quality of dispersants?

The effectiveness of the selected wetting and dispersing agents can be evaluated using the following methods:

01 Fineness Measurement

The dispersion process of pigments in paint is generally determined using a “scraper fineness gauge.” ASTM D1210-64 and GB/T 1724-1979 outline the procedures for measuring fineness commonly used in the paint industry. This method measures the coarsest pigment particles present in the pigment dispersion. Different paint products have different fineness requirements.

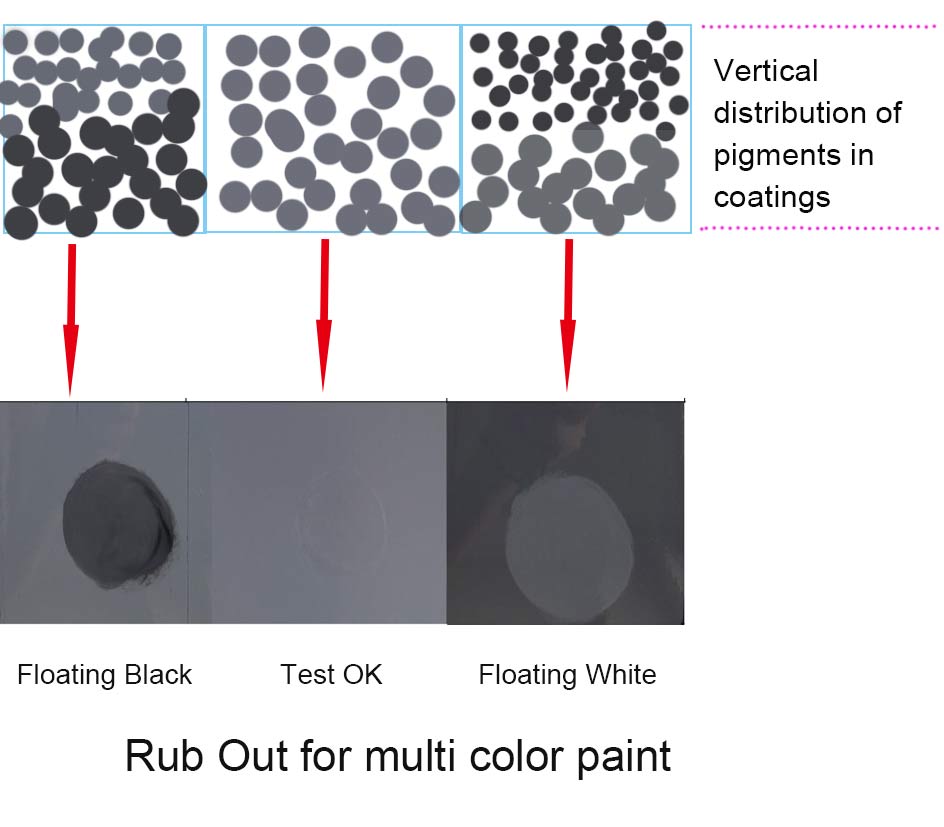

The “rub-out” test is used to evaluate the floating and blooming behavior of mixed pigments (multi-colored paints).

The specific steps for the Rub Out test on paint with added dispersant are as follows:

-

Thoroughly stir the paint to be tested until it is uniformly mixed.

-

Use a wet film applicator or a smooth scraper to evenly apply the paint on cardboard, and let it dry naturally.

-

Just before the paint is about to dry, rub a part of the film with the index finger until the entire film is completely dry.

-

Compare the color difference between the rubbed area and the other areas.

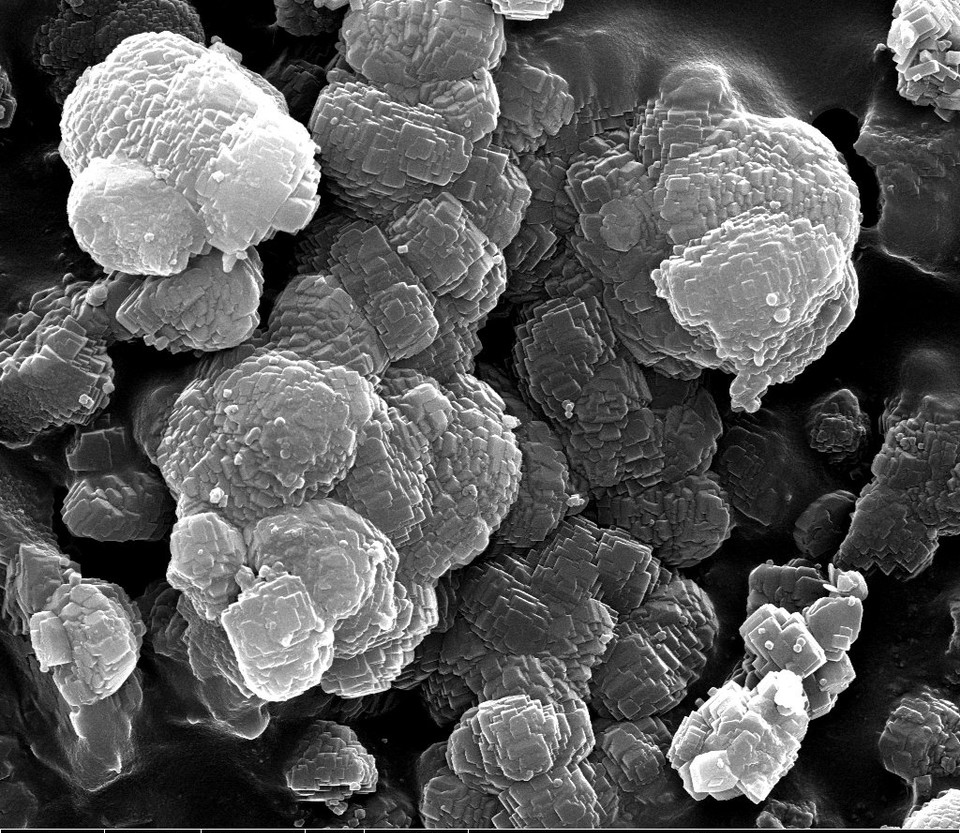

Electron microscopy can observe the particle size distribution and agglomeration state of pigments in wet paints, including phenomena like flocculation and precipitation. It can also observe the pigment particle size distribution and state in the dry paint film.

Contrast Ratio Method:

- Use a standard white or black substrate (for example, a standard contrast card).

- Apply a certain thickness of the test paint onto the substrate.

- Determine the color strength by measuring the light reflectance value of the dried paint film in terms of its coverage over the substrate.

- The contrast ratio refers to the ratio of the reflectance value of the paint film over the black area to that over the white area. The higher the ratio, the better the color strength.

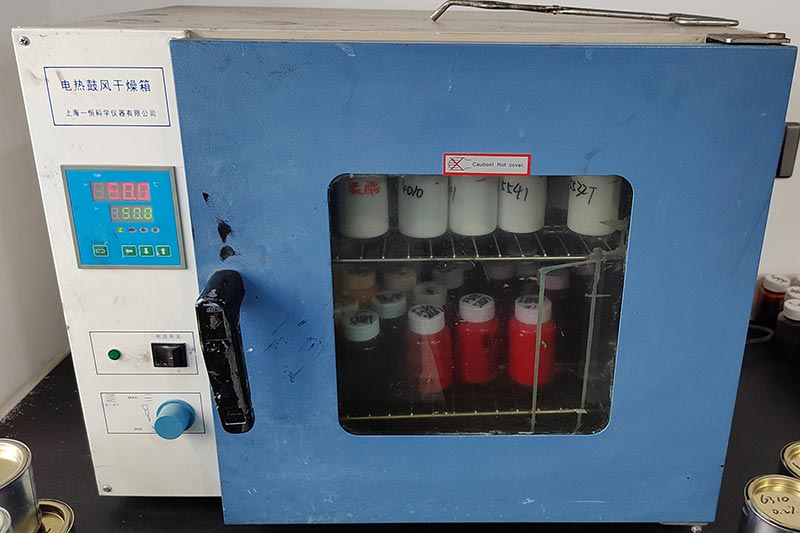

- Sample Preparation: Ready fresh paint samples and store them at specified temperatures, such as room temperature or up to 50°C, in a climate-controlled environment.

- Regular Evaluation: Periodically examine samples for changes in properties such as separation, color, or viscosity, and conduct performance tests to compare with initial data.

- Analysis and Reporting: Document observations, analyze stability over time, and compile findings into a report to guide storage and shelf-life recommendations.

If the dispersion is poor, particles will flocculate after storage, leading to increased viscosity. This indicates incomplete dispersion and poor system stability.

The gloss and transparency (for transparent pigments) of the paint film are important indicators of appropriate stabilization and can be used to evaluate the correct dosage of additives. Well-dispersed pigments result in a paint film with low surface roughness, low diffuse reflection of light, high gloss, and high transparency. Gloss can be measured with a gloss meter, and transparency can be visually inspected or measured with a spectrophotometer.