Ever found yourself staring at a freshly painted wall, only to notice unsightly bubbles or streaks ruining the perfect finish? If so, you’re not alone. It’s issues like these that highlight the crucial role of paint additives in achieving that flawless look.

Paint additives are not just an optional extra; they’re essential for professional-quality results. From defoamers to thickeners, each additive has a specific function that addresses common painting challenges.

- Why Are Paint Additives Essential?

During the Production Process:Dispersants,Promote pigment wetting and reduce dispersion time.

Anti-settling Agents, Prevent pigment settling and agglomeration.

During the Application Process:Thixotropic Agents, Prevent paint sagging when applied to walls.

The effectiveness of paint additives lies in their ability to modify the chemical and physical properties of the paint. By interacting with the paint’s base components, additives can enhance its flow, ease of application, and durability. This scientific approach ensures that paint not only looks good when applied but also stands the test of time.

2.

Factors such as the type of surface, environmental conditions, and the specific challenges of your project should guide your choice.

The following are various additives used in paints.

2.1 Dispersing Agent

Dispersing agents help distribute pigments evenly throughout the paint, preventing clumping and settling. Together, they enhance the paint’s appearance and performance.

Dispersants serve three key functions in paint formulations:

- Reduce Viscosity: They lower the overall viscosity of the paint, making it easier to mix, apply, and handle.

- Prevent Settlement: By stabilizing the pigment particles in suspension, dispersants prevent them from settling at the bottom, ensuring a uniform distribution throughout the paint.

3. Enhance Color Development: Dispersants aid in breaking down pigment agglomerates, which maximizes the surface area of pigments exposed to light. This process enhances the vividness and brightness of the paint’s color.

2.2 Defoamer

Defoamers are specialized chemicals used to eliminate unwanted bubbles that form in various materials and processes. These bubbles can arise during the manufacturing, application, or curing phases of products, particularly in liquids such as paints, coatings, and other chemical formulations. The presence of these bubbles can affect the quality and appearance of the final product, making defoamers crucial for ensuring a smooth, defect-free finish.

Defoamers

- Eliminate bubbles that form during the production process.

- Remove bubbles that appear on the surface of the base material.

- Eradicate bubbles produced during the application process.

- Dissipate bubbles that emerge during the paint film-forming process.

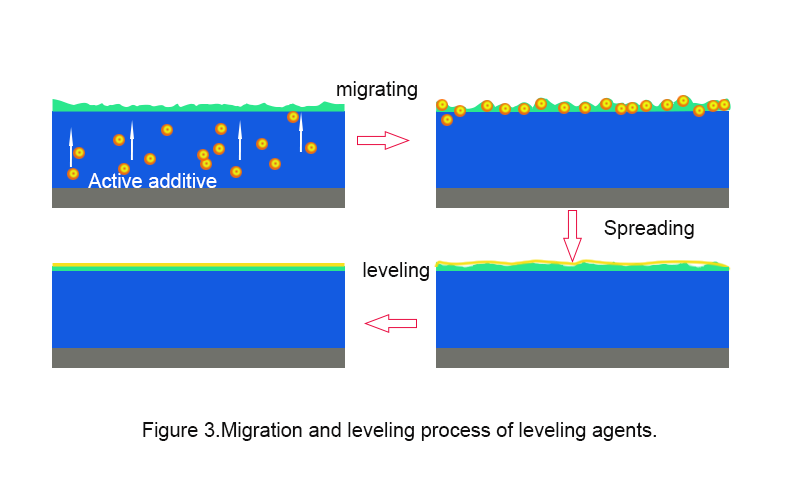

2.3 Leveling Agent

Leveling agents are additives used in paint and coating formulations to enhance the surface finish of the applied film. They work by reducing surface tension, which promotes a uniform coating thickness and helps to eliminate surface defects such as brush marks, orange peel, and pinholes. Leveling agents ensure a smooth, even surface appearance, improving both the aesthetic and protective qualities of the coating.

Two main kind of leveling agent

Silicone Leveling Agent:Low surface tension, which allows them to migrate more rapidly to the surface of the paint film.

Limited compatibility with the resin system, leading to faster migration and a more pronounced effect on the early stages of leveling

Silicone Free Leveling Agent:Slower migration speed compared to silicone-based leveling agents, resulting in their effect being more significant in the later stages of leveling.

Have a relatively higher surface tension, providing a greater leveling force, which makes them more advantageous in providing the final leveling effect.

2.4 Substrate Wetting Agent

A substrate wetting agent is a chemical additive used in coatings, paints, inks, and other formulations to enhance the wetting of the surface to which the product is applied. Wetting agents reduce the surface tension of the liquid, allowing it to spread more evenly over the substrate. This improved wetting helps ensure a uniform coating, better adhesion, and penetration into the substrate, which is especially important in applications involving porous, rough, or low-energy surfaces (such as plastics and metals).

-

-

Enhance the adhesion and gloss of the paint.

-

2.5 Adhesion Promoter

An adhesion promoter, also known as a coupling agent, is a substance that is added to a material to increase the bond strength between it and a subsequent layer. This chemical is often used in paint, coatings, adhesives, and plastics to improve the adhesion between the substrate (the surface being coated or bonded) and the coating or adhesive applied to it.

2.6 Anti-skinning agents

Anti-skinning agents are additives that prevent the formation of a gel film on the surface of the paint due to oxidation and polymerization during storage.

Anti-skinning Mechanism

1. Free Radical Termination:

During the film formation process of paint, free radicals are generated. Anti-skinning agents can capture these free radicals, interrupting the oxidation and polymerization reactions that lead to skin formation.

2. Controlling the Activity of Driers:

Driers, such as cobalt or manganese, are catalysts that accelerate the drying process of paint. However, they can also promote skin formation. By controlling the activity of driers, the formation of skin can be delayed or prevented.

3. Oxygen Isolation:

Anti-skinning agents have a relatively high vapor pressure and are easily volatile. The vapor generated by anti-skinning agents fills the space inside the paint can, isolating the paint film surface from the air and preventing oxidation.

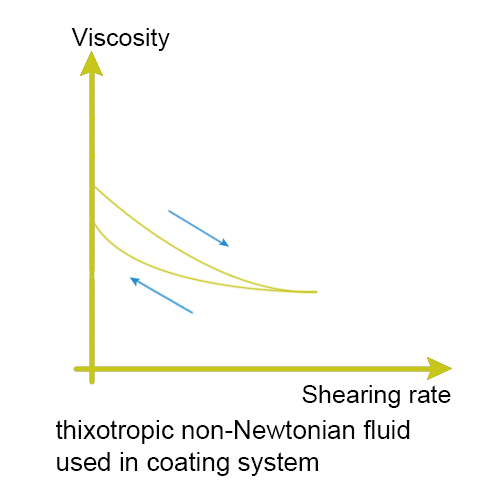

2.7 Rheology Modifier

A rheology modifier agent, also known as a rheology control agent or thickener, is a substance added to a liquid or a mixture to alter its flow properties or viscosity. These agents are used in various applications, including paints, coatings, inks, cosmetics, personal care products, and food products, to achieve desired consistency, stability, and performance.

As shown in the figure, the rheology modifiers used in paint systems have various chemical structures and operating principles, but their basic mode of action is similar. They all form a network structure in the system, providing high viscosity during the storage process under low shear forces.

Once sufficient external shear forces are applied, the micro-network structure is disrupted, and the viscosity quickly decreases, providing the low viscosity needed during construction.

2.8

Emulsifiers are crucial in paint formulations that mix oil and water, helping to stabilize the mixture and ensure a uniform texture. They play a vital role in the production of emulsion paints, contributing to their ease of application and consistent finish.

Emulsifiers are a class of substances that can make two or more immiscible liquid components form a stable emulsion.

Emulsion is a mixture of two immiscible liquids, one of which is dispersed in the other in the form of fine droplets. The dispersed liquid is called the dispersed phase, and the liquid in which it is dispersed is called the continuous phase.

Emulsifiers work by:

- Reducing the interfacial tension between the two liquids. This makes it easier for the droplets of the dispersed phase to break up and form a stable emulsion.

- Forming a strong film around the droplets of the dispersed phase. This film prevents the droplets from coalescing and breaking the emulsion.

- Providing an electrical charge to the droplets of the dispersed phase. This charge prevents the droplets from aggregating due to electrostatic repulsion.

2.9 Anti Graffiti Agent

An Anti-Graffiti agent, also known as an anti-graffiti coating, is a special surface treatment applied to prevent or reduce the adhesion and permanency of graffiti on various surfaces.

Easy to clean mark pen’s dirty

Function:

- Creates a barrier between the surface and the paint used in graffiti.

- Makes it easier to remove graffiti without damaging the underlying surface.

- Can be sacrificial (temporary) or permanent depending on the type.

2.10 Matting Agent

A matting agent is an additive used in paints, coatings, and inks to reduce gloss and create a matte or satin finish.

From grossy black to matte black

Function:

- Matting agents scatter incoming light, preventing a reflective and shiny surface.

- This scattering effect reduces the perception of gloss, resulting in a duller or non-reflective appearance.

Types:

- Silica: Commonly used, available in various particle sizes affecting the level of matting and surface smoothness.

- Waxes: Float to the surface of the paint film, providing a matte effect with good water repellency.

- Fillers: Can be mineral-based like talc or calcium carbonate, offering matting alongside other properties like bulking and texture.

2.11

UV absorbers protect the paint from the harmful effects of ultraviolet light, prolonging its color and integrity. Antioxidants prevent oxidation, a process that can lead to paint degradation. Both additives extend the life of the paint film.

UV Absorbers:

- Function: Absorb harmful ultraviolet (UV) radiation from sunlight, preventing it from reaching and damaging the material.

- Mechanism: Absorb UV photons (packets of light energy) and convert them into heat, which is then dissipated harmlessly.

- Benefits: Protects materials from fading, discoloration, and degradation caused by UV exposure.

- Applications: Used in various materials like plastics, paints, textiles, cosmetics, and sunscreens.

- Types: Different types of UV absorbers exist, each absorbing specific wavelengths of UV radiation.

Antioxidants:

- Function: Delay or prevent the oxidation process, which can occur due to exposure to light, heat, oxygen, or free radicals.

- Mechanism: Scavenge free radicals, highly reactive molecules that can damage materials by breaking down their chemical bonds.

- Benefits: Protects materials from degradation, cracking, and loss of strength caused by oxidation.

- Applications: Used in various materials like plastics, rubber, lubricants, food, and pharmaceuticals.

- Types: Different types of antioxidants exist, each with varying effectiveness against different types of free radicals.

2.12

Fungicides and biocides protect paint from fungal and microbial growth, which can cause discoloration and degradation. These additives are particularly important for paints used in damp environments.

2.13

pH adjusters are used to stabilize the pH level of paint, ensuring the stability of the formulation and preventing unwanted chemical reactions that can affect the paint’s performance.

2.14

Antistatic agents reduce the buildup of static electricity on the paint surface, while conductive agents improve the electrical conductivity. Both are important for applications requiring control over electrical properties.

2.15

Catalysts speed up the chemical reactions in the paint drying process without being consumed themselves. They are essential for achieving the desired drying time and properties of the paint