What is substrate wetting agents?

Different from conventional solvent-based coatings, in modern waterborne coating systems, especially waterborne wood coatings and waterborne industrial coatings, the high surface tension of water (over 70mN/m) is much larger than that of common substrates. This makes it difficult for the coating itself to wet low surface tension substrates. To achieve good wetting of the substrate in these coating systems, additives must be added to lower the surface tension of the system to make it smaller than that of the substrate, thus achieving good wetting. Substrate wetting agents were developed to meet this requirement.

Dynamic surface tension and static surface tension

Since substrate wetting in the application of coatings and inks is a dynamic process, the factor of time must be considered when discussing the performance of substrate wetting. This is especially important for some fast-working systems, such as high-speed printing inks and inkjet systems.

The speed of wetting by additives is usually measured by dynamic surface tension. Dynamic surface tension is a concept relative to static surface tension. Static surface tension usually reflects the ability of additives to reduce surface tension; the lower the static surface tension, the stronger the ability of the additives to reduce surface tension. In contrast, dynamic surface tension reflects the speed at which additives reduce surface tension; the lower the dynamic surface tension, the faster the additives reduce surface tension.

Static surface tension and dynamic surface tension have different requirements for the structure. Sometimes additives with low static surface tension may not necessarily have low dynamic surface tension. This is also the reason why some surfactants such as organosilicon and organic fluorine, which have very low static surface tension, may not necessarily have low dynamic surface tension.

In the formulation of waterborne coatings, different wetting agents can be selected according to different usage requirements, ultimately achieving the optimization of the formula.

Classification of substrate wetting agents

Usually, organosilicon and organic fluorine wetting agents focus on providing excellent static surface tension, while acetylene glycol and their derivatives focus on providing excellent dynamic surface tension. In addition, alkynediol-based additives have the advantage of providing related wetting properties while also providing defoaming capabilities, which is particularly important in waterborne systems.

Organosilicone substrate wetting agents can be divided into two types: trisiloxane-based organosilicone wetting agents and non-trisiloxane organosilicone wetting agents. Trisiloxane-based wetting agents can achieve a surface tension close to 21, making them suitable for wetting some extremely difficult-to-wet substrates, such as low-surface-tension plastics. However, trisiloxane-based wetting agents are sensitive to pH, and when the pH is outside the range of 6-8, isomerization reactions can occur, causing the agent to fail. To solve this problem, some non-trisiloxane wetting agents have been developed. Through specific structural design, the isomerization reaction of trisiloxane-based additives is avoided, but their surface tension can only reach about 23-24.

Organosilicone substrate wetting agents

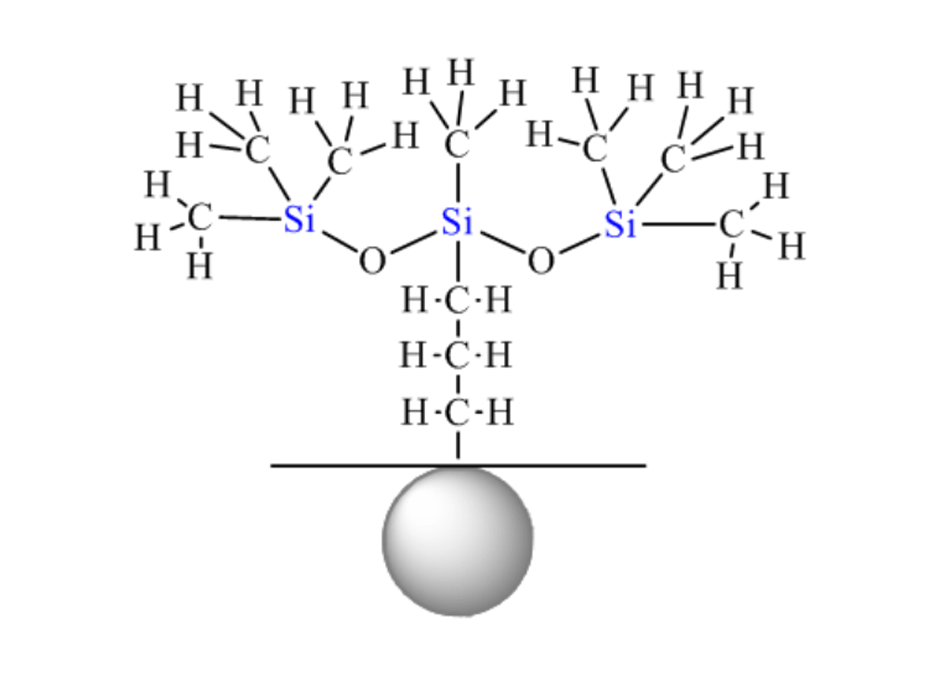

Substrate wetting agents are actually a special type of polyether-modified silicone oil with a typically small molecular weight. Since the rapid wetting of substrates is a dynamic process, and according to the principles of physical chemistry, the working principle of wetting agents is to quickly migrate to the surface of the system, reducing the surface tension of the system to achieve the effect of substrate wetting. According to the viewpoint of molecular motion theory, the migration speed of molecules largely depends on their molecular weight. The smaller the molecular weight, the relatively faster the migration speed. Therefore, polyether-modified silicone oils with relatively small molecular weights are often used as substrate wetting agents in waterborne systems. From a structural perspective, polyether-modified silicone oils used as substrate wetting agents usually contain only one polyether chain, that is, the m value is usually 1, and the n value is also small, usually no more than 4.

Further research has found that when polyether-modified silicone oils used as substrate wetting agents are applied to waterborne systems, due to their unique structure (see Figure left), the organosilicon chain segments can be fully extended, exposing a large number of methyl-CH3 groups to the outside, thus greatly reducing the surface tension of the system. Usually, medium to high molecular weight polyether-modified silicone oils in waterborne systems can only reduce the surface tension to between 25-26N·m-1, while small-molecule substrate wetting agents can usually reduce the surface tension to below 22N·m-1, with the lowest reaching 20-21N·m-1. Because substrate wetting agents reduce the surface tension of waterborne systems to between 20-21N·m-1, waterborne coatings with added substrate wetting agents can wet most low surface tension substrates, including the notoriously difficult-to-wet polytetrafluoroethylene substrates. At the same time, because substrate wetting agents can reduce the surface tension of waterborne systems to a very low level, they can impart good shrinkage prevention performance and atomization effects during spray application to the system.

Due to the small molecular weight of the substrate wetting agent, its organosilicon chain is very short, and thus it cannot provide a good slipperiness to the paint film surface (usually, slipperiness comes from longer organosilicon chains). In other words, when there is a requirement for the slipperiness of the paint film, the substrate wetting agent is usually used in combination with a high molecular weight organosilicon leveling agent, which is also an important difference between the substrate wetting agent and the leveling agent.