What type of resin is used in paint?

In the world of paint, the medium can often be as crucial as the message. Resins, often used to imbue paints with specific properties, come in various types. Each brings its unique flair to the canvas. Let’s delve into the different classifications of resins used in paint.

The type of resins are epoxy resin, alkyd resin, acrylic resin, unsaturated polyurethane, fluorocarbon resin, phenolic resin, nitrocellulose resin, amino resin, vinyl resin.

Let me introduce them one by one.

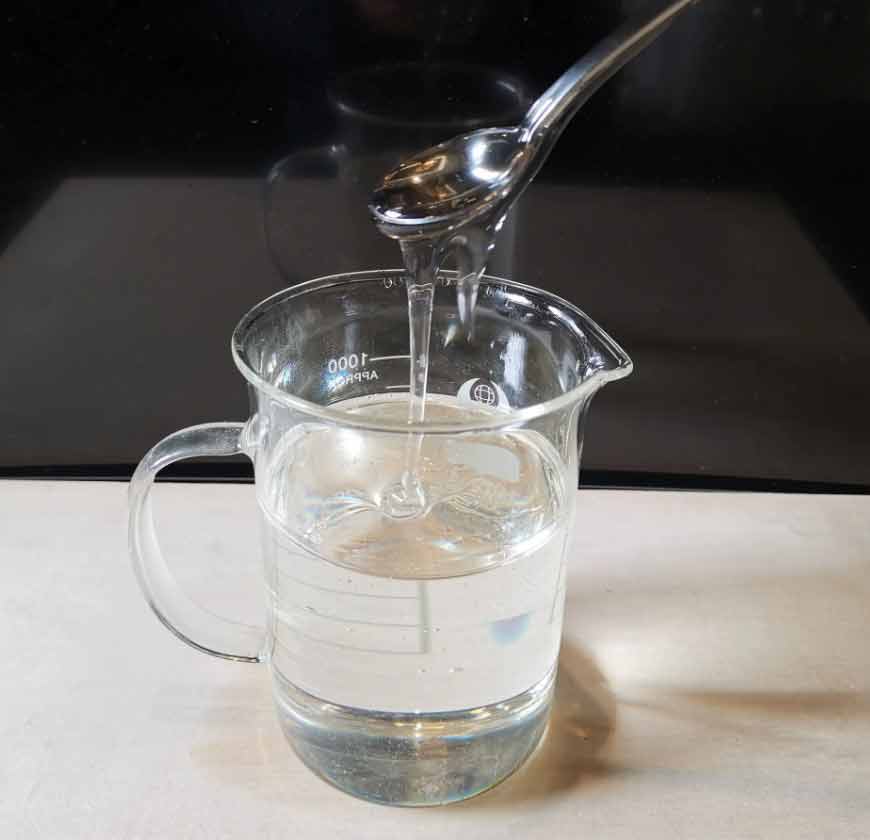

Epoxy resins are renowned for their outstanding adhesion, mechanical properties, and chemical resistance. Often used in protective coatings, they provide a glossy, robust finish that’s hard to rival.

Click the link to see 5 properties of Epoxy resin paint

Derived from polyols and acids, alkyd resins are popular in gloss-enhancing applications. They dry quickly and offer excellent durability, making them a favorite for both artists and industrial applications.

Acrylic resins are known for their excellent clarity and weather resistance. Their fast-drying nature combined with their ability to retain color makes them a top choice for outdoor paints.

This type of resin boasts flexibility and robust adhesive properties. It’s often employed in coatings that require resistance to environmental factors and chemical abrasions.

For those seeking the pinnacle of resistance — be it to chemicals, weather, or UV radiation — fluorocarbon resins are the go-to. Their unparalleled longevity means that coatings remain vibrant and unscathed for years.

Phenolic resins are known for their high heat resistance and excellent adhesive properties. They’re often found in applications requiring thermal stability, such as industrial coatings.

Valued for its fast-drying properties, nitrocellulose resin is a mainstay in nail polishes and some automotive paints. It offers a smooth, mirror-like finish that’s hard to beat.

Amino resins, often used in conjunction with alkyd and acrylic resins, enhance the overall durability and heat resistance of the paint. Their versatility makes them a popular choice in various coating applications.

Vinyl resins are prized for their chemical resistance and robustness. They’re often employed in industrial coatings, especially where protection against harsh chemicals is paramount.

In Conclusion

The world of resins is vast and varied, with each type offering unique properties that can elevate your painting project. Whether you’re an artist seeking a specific finish or someone looking to protect industrial equipment, understanding the nuances of these resins can make all the difference. As always, choose wisely and let your creativity shine